Ayabe Factory

Unlocking the full potential of on-site workers through curated automation and skill-less operation

OMRON Ayabe Factory is the site of ultra-high-mix low-volume production, where we manufacture approximately 20,000 items, ranging from sensors a few centimeters in size to inspection devices that are several meters large. It is mainly an assembly factory where high-quality products are efficiently produced by finely coordinating product design and process design activities. Processes within the production line that do not generate added value, such as transport, are automated to lessen the burden of on-site workers. Data obtained from the production floor is analyzed to visualize improvement points by uncovering procedural factors that affect production efficiency and quality. Tasks that traditionally required the skill and knowledge of veteran workers have been transformed into skill-free operations through automation.

Automating parts transport with mobile robots to allow human workers to focus on product value improvement

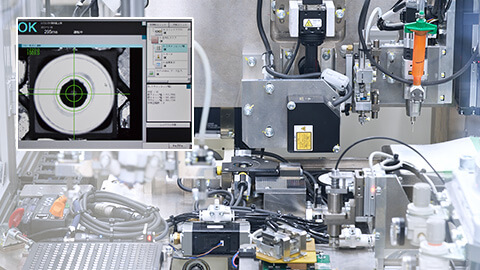

Enabling optimally timed maintenance through predictive management of optical element alignment device

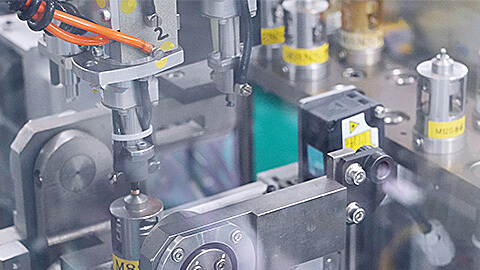

Detecting the slightest shifts in robot hand position to reduce facility downtime and part loss

Enabling low-cost automation of inter-process material handling with compact autonomous transport robots

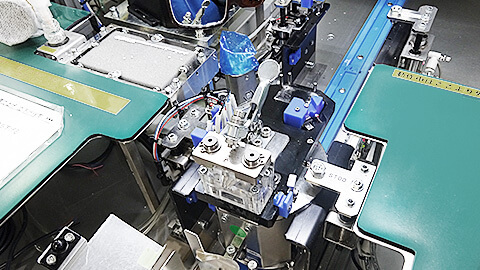

Robotizing complex soldering into skill-free operation without compromising precision or speed

Ayabe Factory

Ayabe

Kyoto 623-0105

Japan

Our Worldwide Production Facilities

Strategically implementing i-Automation! to create the factory of the future

Read more