Industrial Robots

Industrial robots and robotics are at the heart of innovative manufacturing. These intelligent and programmable machines can automate repetitive production and material handling tasks, such as assembly, pick and place, packaging, and inspection.

How can we help you?

If you have a question or would like to ask for a quote, please contact us or send a request.

Kontakta mig Robotteknik

Tack för din förfrågan. Vi återkommer inom kort.

Vi har tekniska problem. Din formulär har inte varit framgångsrik. Vi ber om ursäkt och försök igen senare.

DownloadOffert för Robotteknik

Fyll i alla obligatoriska fält. Vänligen fyll i alla fält markerade med *. Dina personliga uppgifter behandlas konfidentiellt.

Tack för din offertförfrågan. Vi återkommer med önskad information inom kort.

Vi har tekniska problem. Din formulär har inte varit framgångsrik. Vi ber om ursäkt och försök igen senare.

DownloadHow are Industrial Robots important?

Robots in manufacturing lines and warehouses are machines that can replicate certain human movements to automate time-consuming and strenuous tasks. In some cases, they can even exceed human capabilities thanks to intelligent algorithms.

Benefits of Industrial Robots in Manufacturing

While industrial robots differ according to technology, robot type, and application, they all have some common benefits.

Robots help improve quality and consistency in production

Robots ensure maximum productivity and throughput

Robots can improve safety

Robots relieve workers for more creative tasks

Robots enable reshoring

Implementation of manufacturing robots

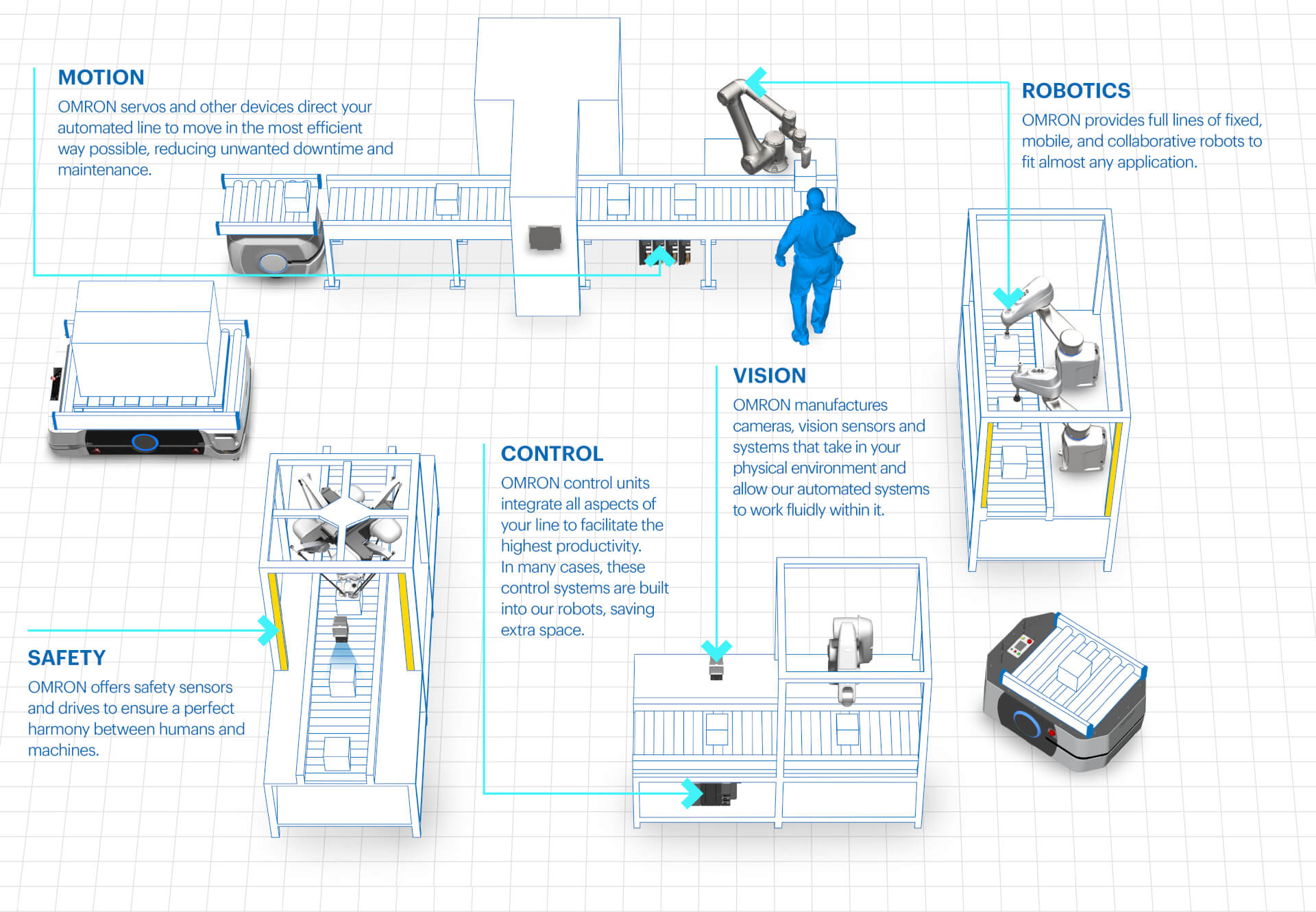

Together with our network of partners, we implement and integrate our core technologies in robotics - as well as motion, control, safety, sensing and vision – including the needed software, simulation and programming tools and services, to enable you to adapt your production to meet the challenges today and in the future.

As OMRON can provide a complete automation solution from one source, integration time is shorter and support seamless. We offer a wide range of services from proof of concept, data science and training, to safety consulting, financing and repairs.

Industrial Robots: key industries

Food & Beverage

Industrial robots are ideal for pick and place applications in food manufacturing, as well as intralogistics and end of line palletizing.

Read more

Automotive Automation

In the automotive industry, industrial robots can take care of a wide range of tasks, from stacking battery cells for electronic cars, to transporting work in progress parts or components with mobile robots, as well as welding, machine tending and assembly with collaborative robots.

Read more

Life Science

In pharmaceutical production, autonomous and collaborative robots can ensure safety and scalability of processes, from vaccine production to personalized medicine.

Read more

Digital & Semiconductor

Industrial robots in semiconductor chip manufacturing. We help the Digital and Semiconductor industry achieve efficient, data-driven and uninterrupted production with our smart manufacturing solutions.

Read more

Other industries

Our automation solutions with robotics cover many manufacturing areas. Besides the ones we highlighted, we also serve sectors like Infrastructure, Power and Energy, and more non-industrial applications.

Read more

Articles & Customer cases

Collaborative robots enhance productivity at CLECA

Palletizing process automated with OMRON TM12 cobots

Mobil robot transporterar avfall på Kymmenedalens centralsjukhus i Finland

Avfallstransport och logistikplanering kräver höga arbetsinsatser i sjukhusmiljöer, och avfallshanteringen är en fysisk uppgift som kräver mycket tid och personal.

Professional help for personal care: Putting a cobot to work

Of the many processes involved in finalising a consumer product, the final step can often be the most intricate. For this OMRON customer, the last step in production is to fasten the cover holding screw, closing up the unit—in this case, an electric shaver. Traditionally, the full process was completed manually, with an electric screwdriver in a multi-step process. This repetitive task is an ideal candidate for the help of an OMRON cobot.

Collaborative robots enhance productivity at CLECA

Mobil robot transporterar avfall på Kymmenedalens centralsjukhus i Finland

Professional help for personal care: Putting a cobot to work

We've got a nearly-infinite combination to fit any production scenes.

Interested?

Kontakta mig Robotteknik

Tack för din förfrågan. Vi återkommer inom kort.

Vi har tekniska problem. Din formulär har inte varit framgångsrik. Vi ber om ursäkt och försök igen senare.

DownloadOffert för Robotteknik

Fyll i alla obligatoriska fält. Vänligen fyll i alla fält markerade med *. Dina personliga uppgifter behandlas konfidentiellt.

Tack för din offertförfrågan. Vi återkommer med önskad information inom kort.

Vi har tekniska problem. Din formulär har inte varit framgångsrik. Vi ber om ursäkt och försök igen senare.

Download