EV transition made easy: Top three challenges to overcome in automotive manufacturing

Publicerat 23 november 2023 i Industry 4.0

Ensuring sufficient space to build the new vehicles

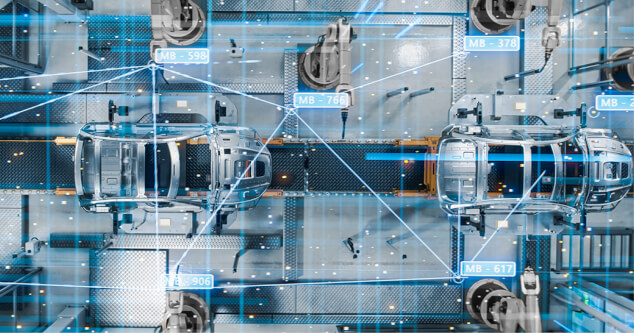

As the production of electric vehicles (EVs) introduces new platforms, manufacturers face the complex challenge of plant capacity. Additional stations can be added to production lines to produce plug-in hybrid vehicles as they share some commonalities with internal combustion engine lines.

For companies manufacturing full battery electric vehicles (BEVs), reusing existing lines is not an option due to the entirely different vehicle structure. They would need to establish a dedicated plant based on projected production volumes or the installation of a specialized line within an existing facility for BEVs.

The good news is that automation offers a solution to optimize space utilization, allowing automakers to maximize efficiency without the need for new facilities. Automation solutions can dramatically improve floor space utilization by making it possible to store parts in ways that might be difficult for a human to reach.

Training their workforce for the future

Estimating levels of demand for the new vehicles

With electric vehicles being relatively new to the market, the automotive industry lacks historical data that can reliably estimate the annual production volume needed to meet consumer demand for a particular EV model. As a result, these estimates are more of an educated guess at this stage.

This means that EV companies’ production lines need to be very scalable and flexible. What might begin as a low-volume production could suddenly rise in demand. That demand could then peak very quickly. Such rapid shifts may call for retooling, and investment in more manpower, a new space dedicated specifically to the new vehicle, or all of the above.

Flexible manufacturing solutions are designed to minimize the costs and downtime associated with vehicle changeover, manage innovation while continuing to support legacy needs, and help companies stay competitive in a rapidly changing market. This adaptability empowers automotive companies to remain competitive in a swiftly evolving market. For instance, collaborative robots can be easily adapted to a variety of tasks, helping to minimize equipment changeover.

Electric vehicle production used to be seen as a distant possibility, but that is no longer the case. As the key players in the industry come together to develop affordable and efficient electric vehicles, OMRON sets itself apart as a premier industrial automation leader. According to Reuters, the market for EV battery components is projected to potentially reach $250 billion by 2030. Automotive manufacturers must now tackle the challenge of meeting increasing demand while also fostering innovation. Discover the valuable insights on how to optimize your processes to meet this growing demand in our whitepaper.

Contact us for more information