Today's challenges to protect and boost your processes

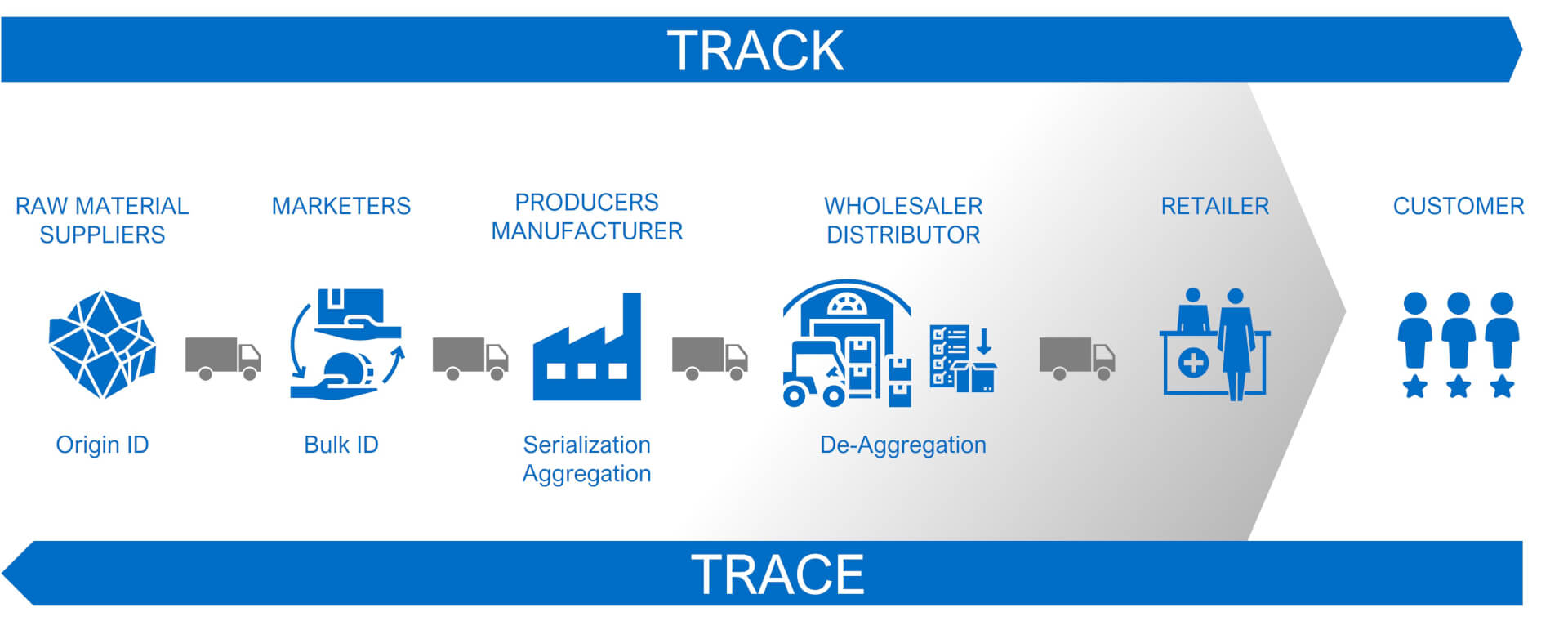

The manufacturing industry is moving at a fast pace and it is hard for producers to keep up with the continuous need for change caused by new regulations, counterfeit operations and individualised consumer needs.

Traceability is vital for protecting your brand and it can also provide valuable information for improving your processes. We use our vast experience in track, trace and control to help manufacturers build robust systems that protect and improve processes; today and tomorrow.

-

OMRON's Traceability 4.0

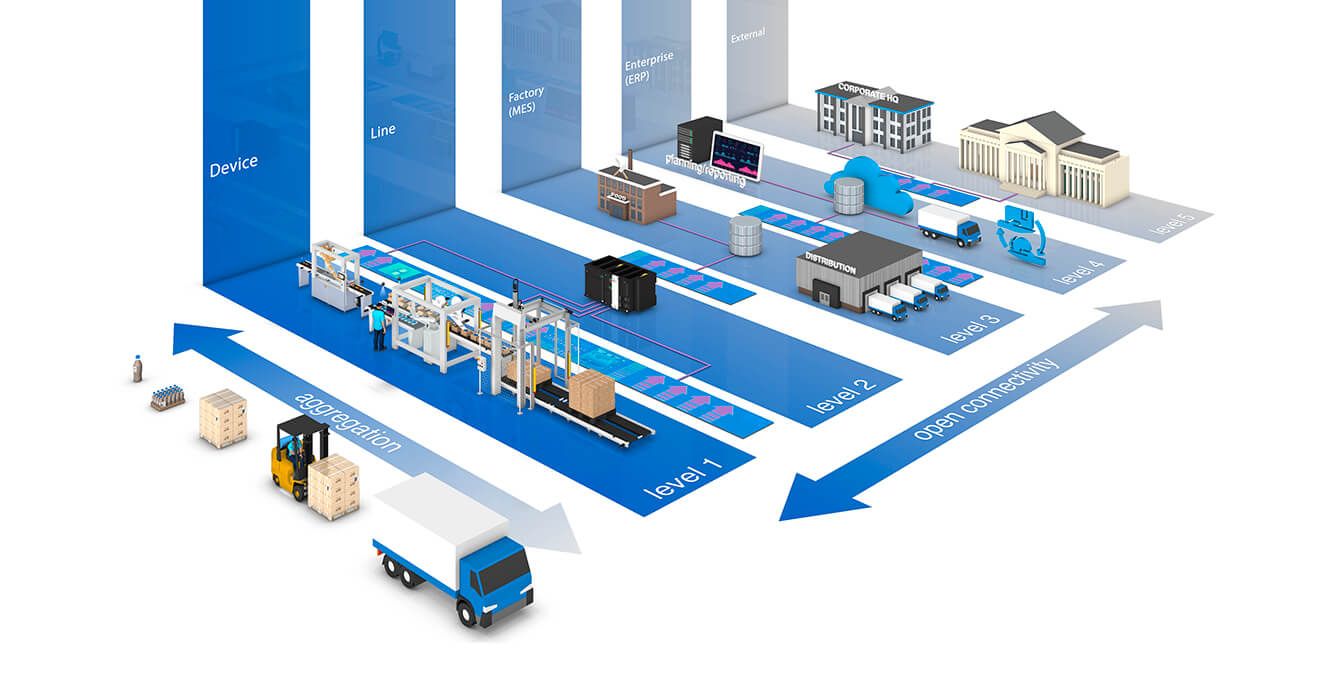

The need to control and have visibility in the automation processes has increased. Our traceability 4.0 connects digital and physical technology to optimize and improve yield. We add additional value with quality components and products. Traceability 4.0 connects information about people, processes, equipment, and parts.

03:32

OMRON's Traceability 4.0

The need to control and have visibility in the automation processes has increased. Our traceability 4.0 connects digital and physical technology to optimize and improve yield. We add additional value with quality components and products. Traceability 4.0 connects information about people, processes, equipment, and parts.Key Applications & Solutions

We offer a complete array of hardware solutions for all your traceability challenges to boost brand protection, regulatory compliance, quality control, and process improvements. Combined with our MVRC approach (Mark, Verify, Read, Communicate), we provide innovative, future proof applications and solutions. Our traceability experience helps you to ensure quality while improving productivity.

- one partner for all your traceability hardware

- successful international track record

- future proof MVRC approach

- combine with sensing, control, safety, vision, motion, robotics

- smart technology for modern day challenges

Benefits of our traceability solutions:

-

Regulatory compliance with traceability directives

-

Identify counterfeit production & illicit trade

-

Targeted recalls pinpointing problems and individual products

-

Increase consumer information & personalisation

-

Improve quality with rich data at product level

Our solutions include:

-

Single source full hardware solution covering all traceability system aspects: laser marking, code quality management tools, reliable code reading, data collection and communication plus RFID

-

Guaranteed performance and fast deployment as all components have been designed to work with our traceability controllers

-

Retrofit solution that can easily be implemented on existing lines without compromising line efficiency

-

Built-in communication capabilities for interfacing with MES and ERP systems

See all our Key Applications & Solutions

Laser Marking

Laser marking provides the most durable marks and easy to read codes to guarantee that parts can be identified throughout the life cycle of the product.

Code Readers & RFID

A major obstacle for effective logistics management is the problem of inconsistent identification and therefore limited traceability. Our wide portfolio of code reading & RFID products help you solve your traceability challenges.

Communication & Implementation

Traceability is all about reliable data collection at all stages of manufacturing, without impacting production efficiency. The challenge is to realize reliable data collection with limited implementation costs.

Code Quality Verification

The quality of the code is the key process parameter to guarantee a reliable traceability system. You want to be able to read 100% of the traceability codes, 100% of the time.

Interesting to read

-

Traceability 4.0 - The fundamental element of global manufacturing Teknisk dokumentation

Traceability 4.0 - The fundamental element of global manufacturing Teknisk dokumentation

Related Products

We offer an extensive portfolio of products within the area of traceability solutions, find them all via the below links: