Navigating the new machinery directive

Publicerat 16 januari 2025 i AI

The European Union’s transition from the 2006/42/EC Machinery Directive to the new Machinery Regulation (2023/1230/EU), effective January 20, 2027, represents a significant shift in legislative requirements for machinery and related products. For system integrators, the regulation introduces stricter requirements for the incorporation of AI-driven systems, autonomous machines, and interconnected equipment. For end users, especially those operating complex machinery systems, preparing for these changes is a strategic necessity.

Continuity in safety goals, innovation in approach

The overarching goal of the new regulation remains the same as its predecessor: ensuring the safe design, construction, and use of machinery. However, the updated regulation seeks to address gaps in the original directive, particularly in light of advancements in digital technologies and the complexities in modern manufacturing. Key updates include a more structured approach to conformity assessments, explicit provisions for digitalization and cybersecurity, and a direct legal application across EU member states without the need for national transpositions.

Embracing the New Legislative Framework (NLF)

One of the notable structural changes is the alignment of the Machinery Regulation with the EU’s New Legislative Framework (NLF). This approach streamlines compliance by harmonizing procedures across different product categories. It also introduces clarity in terminology and processes, particularly for high-risk machinery and new risks associated with digital technologies such as AI and connected systems.

The role of AI, cybersecurity, and digitalization

Perhaps the most transformative aspect of the new Machinery Regulation is its focus on digital technologies. It explicitly addresses risks associated with AI, machine learning, and interconnected devices. For example, systems with partially or fully self-evolving behavior—commonly found in AI-powered equipment—now require stricter third-party assessments. This ensures that adaptive systems maintain safety even as they evolve over time.

Cybersecurity is another critical pillar. Machinery must be designed to withstand malicious attempts to corrupt safety-critical components or software. This mandate aligns with the broader Cyber Resilience Act but is tailored to machinery safety, addressing risks unique to manufacturing environments.

Digital documentation is a practical addition to the regulation, allowing manufacturers to provide user manuals and conformity declarations online. While this reduces environmental impact and operational costs, it requires manufacturers to ensure that digital resources remain accessible for at least ten years after a product’s market entry.

Implications for automation projects

For those in the automation industry, the Machinery Regulation has specific ramifications:

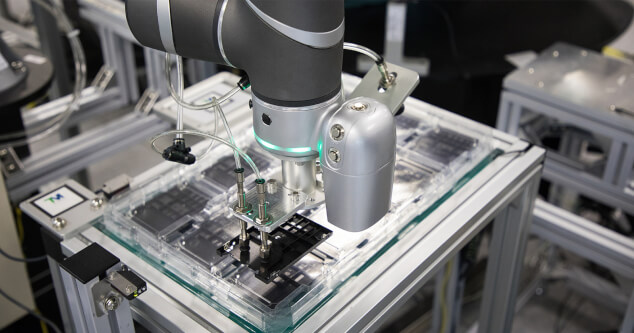

- Collaborative robotics: The new Machinery Regulation seeks to address safety risks associated with human-robot collaboration. Cobots often operate in close proximity to humans, and companies must ensure their safety functions remain reliable, even in dynamic environments. The regulation introduces stricter requirements for cobots incorporating AI or adaptive behaviors, particularly if these systems impact safety-critical functions. In such cases, third-party conformity assessments may be required to validate compliance.

- Integration of autonomous systems: Autonomous machines, such as mobile robots, must now include specialized monitoring functions that allow supervisors to remotely access real-time information about the machine and intervene when necessary. This includes the ability to stop, start, or reposition the robot to ensure safety without introducing additional risks. Importantly, the regulation stipulates that supervision can be conducted either directly or indirectly—such as through camera systems—provided the machine’s movement and working area are fully observable.

- Artificial intelligence: Systems with partially or fully self-learning behavior, such as those leveraging machine learning, must ensure that their adaptive functionality does not compromise safety. The regulation explicitly requires that safety-critical AI systems undergo stringent risk assessments and, in many cases, third-party conformity evaluations to verify compliance. Additionally, AI systems must not make changes during their learning phase that could lead to unforeseen risks or hazards.

- Cybersecurity in connected systems: The Machinery Regulation also addresses the growing risks associated with interconnected and remotely operated machinery. Machines must now be designed to withstand unauthorized access or tampering that could compromise safety-critical functions. This includes protections against malicious interference via physical connections, such as USB ports, or digital channels, such as networked systems.

Preparing for compliance: A proactive approach

The Machinery Regulation’s staggered timeline gives companies working on industrial automation projects a critical window to prepare, but the absence of a transition period means full compliance must be achieved by the January 2027 deadline. To ensure readiness, businesses should start by conducting a comprehensive review of existing machinery and systems to identify gaps relative to the new requirements. Particular attention should be given to provisions for high-risk machinery, digital safety components, and cybersecurity vulnerabilities, as these are key areas of focus in the updated regulation.

Adopting harmonized standards early—where available—can also help streamline the compliance process, even as many standards are still under revision. Training is another essential step, equipping teams with the knowledge required to handle new technologies.

For system integrators and end users, the new Machinery Regulation offers a framework for driving innovation and ensuring safety in an increasingly digital manufacturing landscape. By acting now, stakeholders can prepare for a seamless transition, capitalize on the opportunities presented, and build resilient systems that meet the demands of the future.