New IoT Processing control sensors E8FC - Flow and E8PC - Pressure

New Flow sensors E8FC and Pressure sensors E8PC present the new generation of innovative solutions to control industrial process with different fluids and gases.

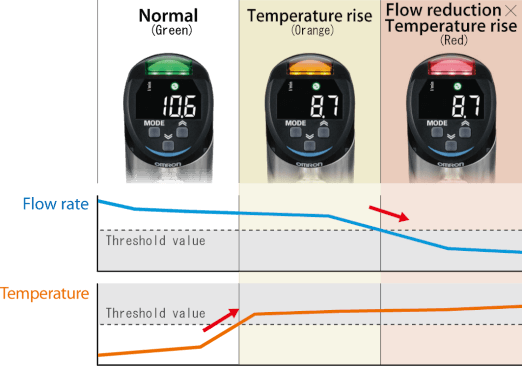

A unique technology with double monitoring of main parameters of flow or pressure. At the same time controls temperature and allows in advance to predict process abnormality by indicating it with bright coloured visual signals and reliably to read exact parameters on the good visible black-white organic indicator.

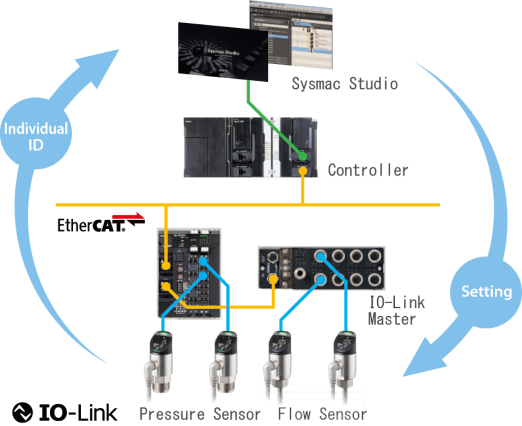

At the same time, thanks to high speed of the IO-Link communication standard COM3, these sensors can transfer information about the monitored system status as well as identify data and parameters of self-diagnostic.

Sensors E8FC/E8PC for flow- and press control complement further our "Vertical Integration Concept" and that allows to transfer monitored processing data from the lowest level of the automation pyramid and transfer settings parameters from the top to down to each sensor.

The new E8FC sensors can be used in the automotive industry to prevent sudden stops and defects in molding and welding machines due to cooling liquids abnormalities. Further, due to precise monitoring hydraulic pressure, the new E8PC can be applied to prevent press and processing defects in different types of pressing machines or in advanced machining centres like CNC or others.

Apart of being suitable for the automotive industry, several other industries can take advantage of this technology. These include industries that value not only identifying one processing mistake or abnormality that can cause huge damage to the whole production process but also to the final product. The new E8FC/E8PC can be used as an effective solution to predict and to indicate those issues in advance.