HB-Maschinenbau and OMRON have teamed up to automate complex manufacturing processes for the construction industry, creating a fully automated assembly line. The solution utilizes OMRON's robotics and vision technologies to improve the speed and accuracy of producing multiple product types. The automated systems ensure that each product meets high standards before reaching the customer. By reducing the reliance on manual labor, the partnership not only boosts productivity but also allows employees to focus on more strategic tasks.

Key Benefits

- Fully automated assembly line enhances efficiency by automating complex manufacturing processes for the construction sector.

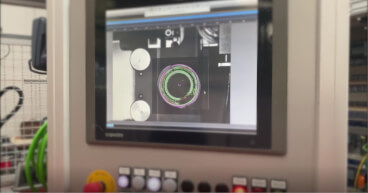

- Vision technology with robotics ensures quality control and reliability

- Scalable automation solution for varied applications, with significant cost/performance benefits.

- Replaced 20-30 manual workstations, enabling employees to focus on more value-adding and creative tasks

Complex production system for a customer in the construction sector uses robotics and vision technology from OMRON

Companies that want to rationalize and automate manual production processes from the ground up, need a holistic approach and perfectly coordinated technologies. It is not enough to start at just one point: “The various steps must interlock seamlessly. Automation expertise is very important,” says Stefan Lemberger, project manager in the automation design department at HB-Maschinenbau GmbH. The company from Metten in the Bavarian district of Deggendorf, is one of Germany's leading mechanical engineering companies and, as an all-in-one supplier, offers a wide range of services relating to individual part production, complete systems and special machines.

When a renowned customer from the construction sector approached the HBMaschinenbau team to automate various, sometimes highly complex manufacturing processes that had previously been outsourced, it was clear that robotics and technology from partner OMRON would be used: “We were particularly interested in proven quality, the smoothest possible integration and a good price-performance ratio. In the area of image processing, we paid attention to prefabricated solutions between image processing and robotics in order to save work.”

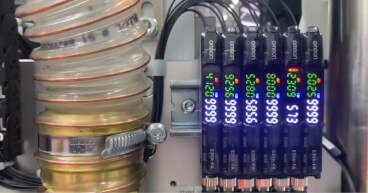

HB-Maschinenbau and OMRON joined forces to implement this project, a fully automated assembly line. It processes components into seven different product types, which differ in the way they are assembled. In some cases, diverse variants of certain individual parts are also installed to obtain a different product.