Today’s Challenge: Reliable data collection

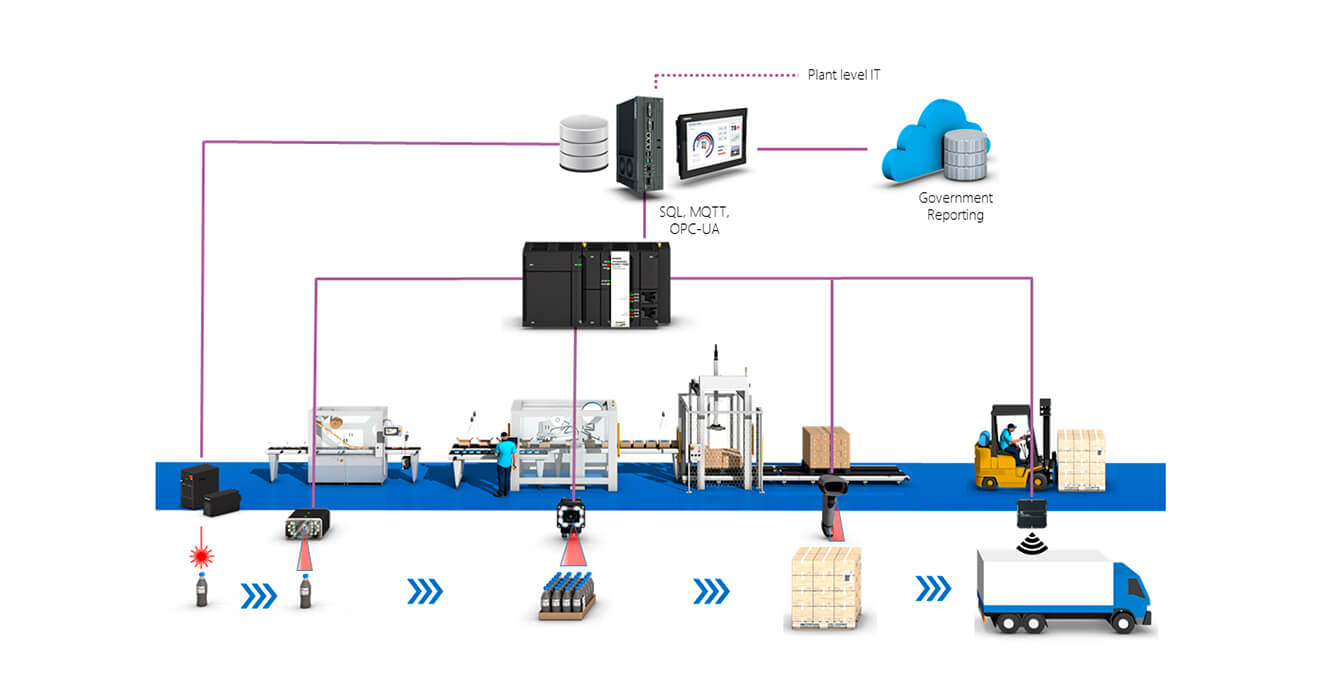

Traceability is all about reliable data collection at all stages of manufacturing, without impacting production efficiency. Existing manufacturing lines that have not been designed for traceability require updates to comply with directives. Custom machine modifications can be costly and take a long time to implement.

Traceability systems need to deliver their data to databases, MES- and ERP systems while keeping up with production speeds. Ambitious compliance deadlines leave very little time for system implementation. The challenge is to realize reliable data collection with limited implementation costs.

Our Solution: Cost saving implementation control

With our database enabled controllers, the traceability system can be implemented separately from existing machine automation, avoiding costly modifications and dependence on machine builders.

Our traceability controllers, combined with OMRON data capture devices, offer a low cost of implementation by greatly reducing the time needed for development and commissioning. The HMI panels, uninterruptable power supplies, and sensors needed to complete the traceability solution are readily available from our extensive automation portfolio.

Benefits of our communication & implementation solutions

-

Fast installation and commissioning

-

Transparent data delivery with built-in SQL and MQTT capabilities

-

Easy handling of rejects and triggering through integrated automation capability

-

Transparent integration with a standardized interface for all OMRON data collection devices

-

Non-intrusive retrofit data collection solution independent from existing line control systems

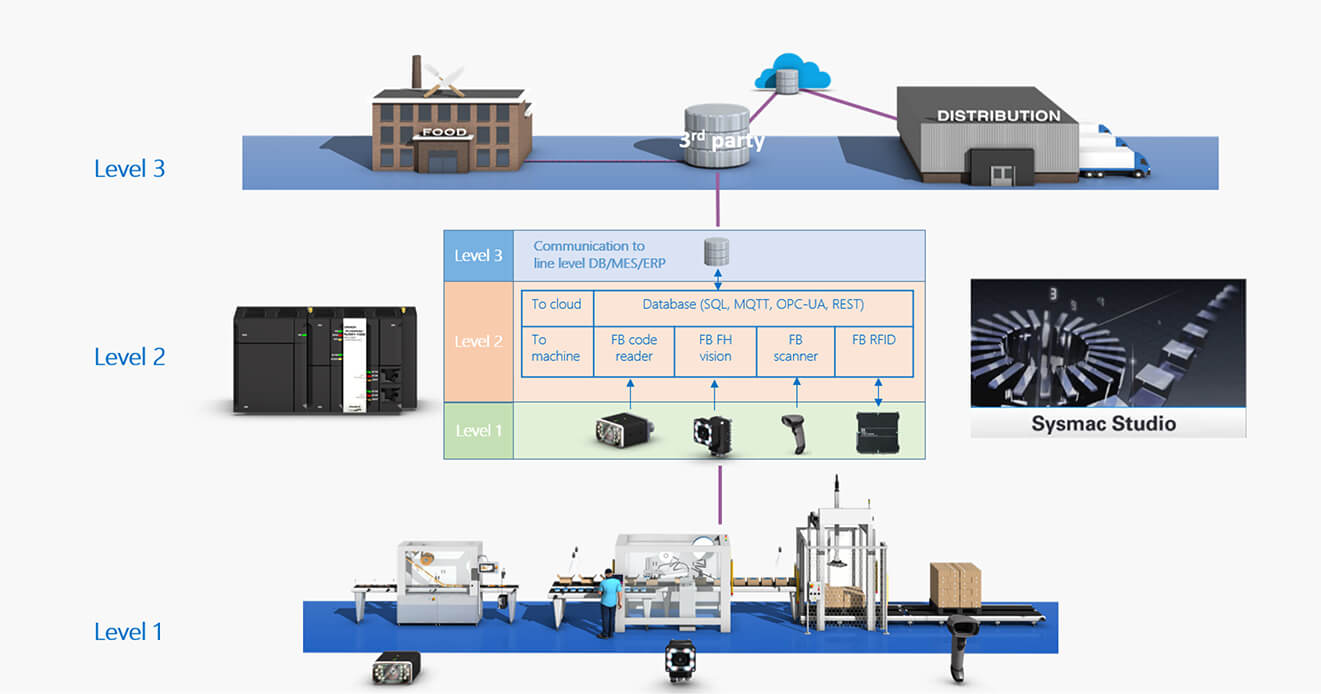

Traceability Toolbox

Reliably collecting traceability data for fast moving consumer goods requires reliable communication between all data capture devices and the traceability system. OMRON has developed the traceability toolbox for it’s Sysmac line of controllers for seamless communication with OMRON barcode scanners, vision systems and RF ID readers. The Traceability toolbox contains standardized function blocks that allow system integrators to quickly create data capture solutions in Sysmac Studio and be confident about performance and reliability.

The OMRON traceability toolbox supports the following data capture devices:

- V330-F/V430-F/V440-F code readers

- F330-F/F430-F vision sensors

- FH / FH-V7 vision systems

- V680S RFID systems

- V450-H/V410-H handheld scanners

See Our Solution in Action

See here how we can help you optimize processes, reduce costs and improve quality.

-

OMRON Traceability - Automotive

Omron Traceability Solution for Automotive Industry is here to help you optimize processes, reduce costs and improve quality. Having a strong product traceability is critical in allowing manufacturers to identify faulty or risk products and initialize a quick and focused containment through the relevant corrective actions or recalls. Having the ability to quickly identify the non-conforming parts or vehicles can accelerate the containment process by reducing checks on unaffected vehicles. This greatly reduces the costs and improves overall efficiency. To find out more, please send your enquiry to: apac_enquiry@

02:07

OMRON Traceability - Automotive

Omron Traceability Solution for Automotive Industry is here to help you optimize processes, reduce costs and improve quality. Having a strong product traceability is critical in allowing manufacturers to identify faulty or risk products and initialize a quick and focused containment through the relevant corrective actions or recalls. Having the ability to quickly identify the non-conforming parts or vehicles can accelerate the containment process by reducing checks on unaffected vehicles. This greatly reduces the costs and improves overall efficiency. To find out more, please send your enquiry to: apac_enquiry@Related Products

-

NA Series -The Sysmac HMI

-

Sysmac controller – NJ1 Series

-

Sysmac controller – NJ5 Series

-

Information & Productivity in a miniaturized size controller

-

Sysmac controller – NX7 Series

-

IPC Machine Controller

-

Industrial Box PC

-

Industrial Panel PC

-

Compact DC-DC UPS with DIN-rail prevents voltage drop and power failure in industrial PCs (IPC)/controllers

See also our other Key Applications & Solutions

Laser Marking

Laser marking provides the most durable marks and easy to read codes to guarantee that parts can be identified throughout the life cycle of the product.

Code Readers & RFID

A major obstacle for effective logistics management is the problem of inconsistent identification and therefore limited traceability. Our wide portfolio of code reading & RFID products help you solve your traceability challenges.

Code Quality Verification

The quality of the code is the key process parameter to guarantee a reliable traceability system. You want to be able to read 100% of the traceability codes, 100% of the time.