Italian Pack and OMRON have joined forces to introduce Argo, an automatic tray sealing machine equipped with an innovative anti-sloshing system, addressing the challenge of packaging liquid and semi-liquid products without spillage.

Argo offers a significant increase in productivity by 30-40%, ensuring high seal quality and hygiene standards. With reduced machine contamination and minimized tray waste, it contributes to sustainability efforts.

Italian Pack's customizable solutions, coupled with OMRON's technical expertise, enable access to new customer segments with high standards, strengthening their market position. Argo represents a successful collaboration, delivering tangible benefits to manufacturers of soups, sauces, and ready meals.

Key benefits:

- No spillage, high productivity: Argo increases productivity by 30-40%.

- Enhanced hygiene: Reduces machine contamination and improves seal quality.

- Sustainable packaging: Minimizes tray waste, contributing to sustainability efforts.

- Customizable solutions: Italian Pack offers flexible, tailored packaging lines.

- Comprehensive support: OMRON provided technical expertise for successful integration and development.

Italian Pack has been in the packaging market since 1988, offering packaging systems for trays, cartons, cans and pouches. Based in Como, the company has built its position in the food market by offering manual and semi-automatic machines with vacuum, gas and skin technologies, complex lines and complete turnkey systems.

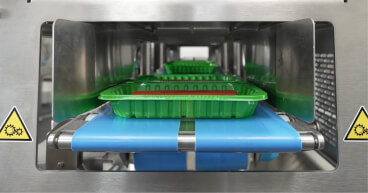

One of the brand's recent challenges has been to provide manufacturers of liquid and semi-liquid food products with a solution capable of operating at high cycle times while avoiding product spillage. This need led to the creation of a new automatic tray packaging line - called Argo - which quickly caught the market's attention because of its special intelligent transport system, called the Smart Liquid System, a solution that uses an innovative, patent-pending anti-sloshing system to package products at high speed, avoiding spillage problems.

Thanks to the innovative anti-sloshing system developed in collaboration with OMRON, Italian Pack can now enter the market for packaging liquid and semi-liquid products with a 30-40% increase in productivity. Specifically, Argo can operate at up to 25 cycles per minute in sealing mode, up to 18 cycles per minute in modified atmosphere (MAP) mode and up to 10 cycles per minute in skin mode.

As well as offering customers increased performance, Argo also provides a tangible benefit in terms of hygiene, meaning less machine contamination, better seal quality and less tray waste, contributing to sustainability.

Contact us for more information