E2C-EDA

High precision positioning inductive proximity sensor with separate amplifier

The separate amplifier inductive sensor family E2C-EDA offers high precision distance positioning and detection. The teach-in function allows simple installation, and with the window function (2 outputs) production tolerance checks can easily be set up and modified.

- Typically several hundred µm detection precision

- Precision distance teaching

- Window function (2 outputs) for production tolerance checks

Specifications & ordering info

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Kontakta mig E2C-EDA

Tack för din förfrågan. Vi återkommer inom kort.

Vi har tekniska problem. Din formulär har inte varit framgångsrik. Vi ber om ursäkt och försök igen senare.

DownloadOffert för E2C-EDA

Fyll i alla obligatoriska fält. Vänligen fyll i alla fält markerade med *. Dina personliga uppgifter behandlas konfidentiellt.

Tack för din offertförfrågan. Vi återkommer med önskad information inom kort.

Vi har tekniska problem. Din formulär har inte varit framgångsrik. Vi ber om ursäkt och försök igen senare.

DownloadPerformance comparison

Environmental resistance

Chemical resistance

Issue: Detergents and chemicals used for cleaning or during the manufacturing process may severly damage (corode) the housings or sensing face of sensors. But apart from these conciously used chemicals, accidentally applied liquids (soft drinks with low pH values or sweat) can unintentionally damage the sensors.

| Solutions |

| * Market standard: basic splash water protection for dry and protected machine environment. |

| ** Tested enhanced high pressure water and saltwater spray protection with our E2A for open factory environment with occasional touching (sweat), cleaning or accidental liquid contact. The optional stainless steel housings may provide additional protection. |

| *** High and highest chemical resistance with our E2EH and E2FQ for frequent cleaning or intense and continuous chemical liquid contact. |

Extreme temperatures

| Issue: Continuously high or low temperatures exceeding the rated specifications quickly damage standard sensors. Suitable materials and/or product design are required for these applications. |

| Solutions: |

| * Market standard: normal ambient temperatures for operation and storage for standard factory environments. |

| ** Specified extended operating temperature range down to -40°C with our E2A for machine operation in lower temperatures. |

| *** High temperature resistance up to 200°C with our E2EH and E2C for applications with high continuous temperatures. |

Changing temperatures

Changing temperatures - performance

| Issue: Temperature variations in machines resulting from the operation, from usage in different regions or even from daily or seasonal fluctuations are very common. The performance and specifications of electronic components are significantly influenced by the ambient temperature resulting e.g. in variations of the sensing distance. The design of electronic circuits, the usage of compensatory elements and the balance of used parts play a vital role in reducing the sensor performance variations due to changing temperatures. |

| Solutions: |

| * Market standard: basic temperature compensation for standard factory environment. |

| ** Designed-in enhanced temperature compensation elements with our E2A for higher operational stability in machine and factory environments even with higher temperature variations. |

| *** Highest temperature influence immunity by separating the sensing head from the electronic parts with our E2EC and E2C for high precision positioning applications with minimal influence by changing temperatures. |

Changing temperatures - lifetime

| Issue: Rapidly changing temperatures and different expansion coefficients can lead to mechanical stress between connecting materials leading to mechanical damage or faster aging. |

| Solutions: |

| * Market standard: sensors designed for standard factory environments – faster aging or damages may occur with frequently or rapidly changing temperatures. |

| ** Designed-in and tested enhanced lifetime with our E2A for machine and factory environments with frequently or rapidly changing temperatures. |

| *** Tested combinations of temperature and mechanical stress for special applications or certifications. |

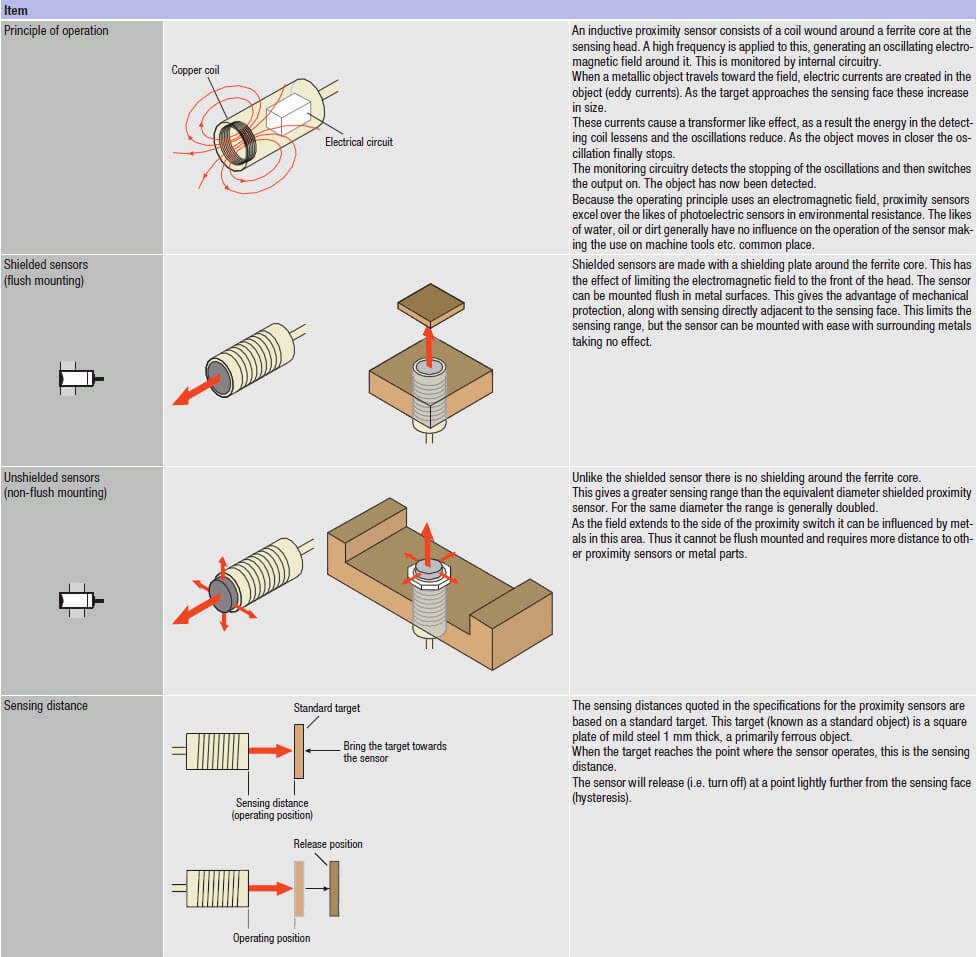

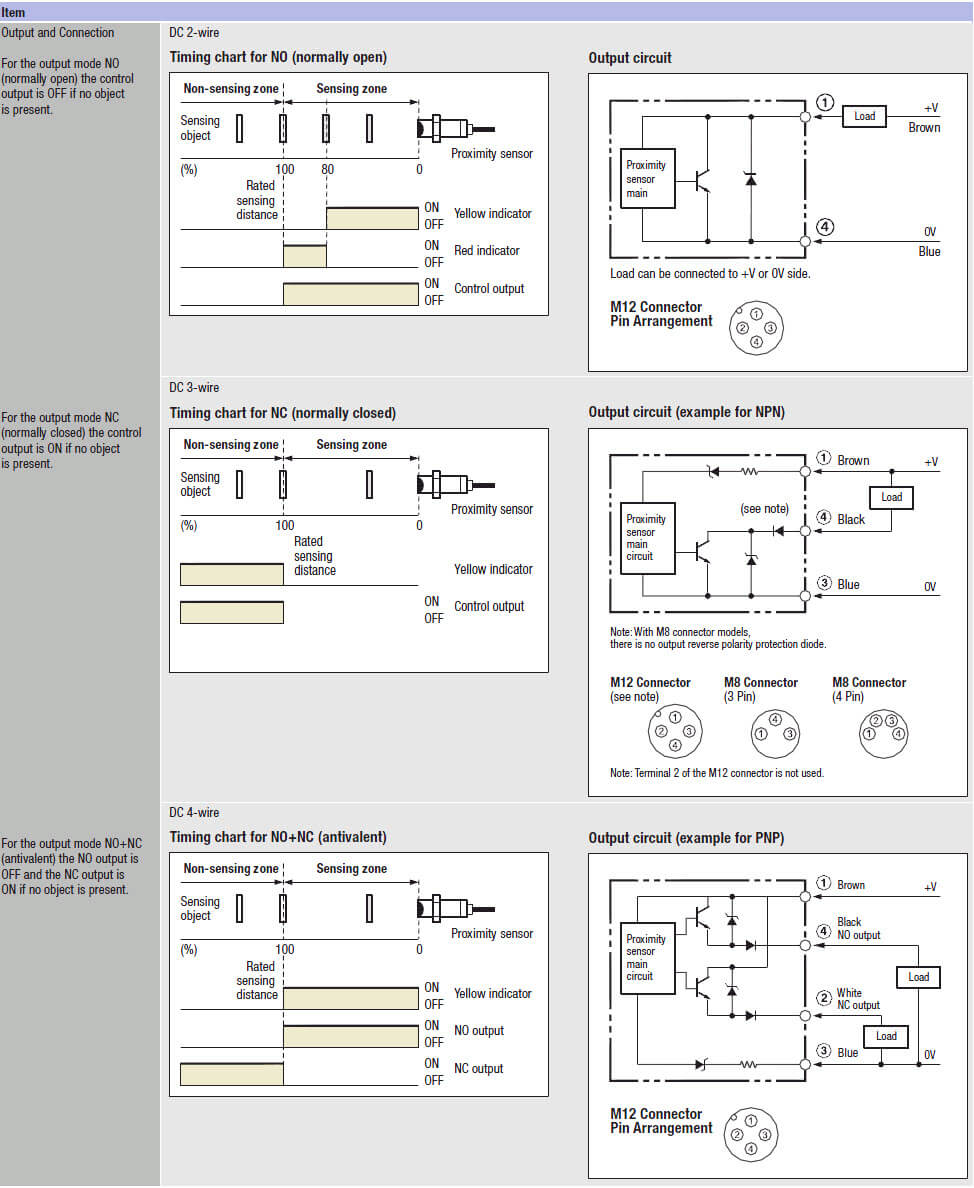

Technical information