E3AS

Advanced direct reflective photoelectric sensors

E3AS Series changes the “way of using” photoelectric sensors

- Wide range of solution up to 1,5m.

- High reliable detection for shiny, uneven & transparent objects.

- Spot beam and Line beam to detect any challenging object.

- Transparent detection objects without reflector.

- OLED display for easy navigation & advance adjustments.

- Compact-sized body can be mounted anywhere.

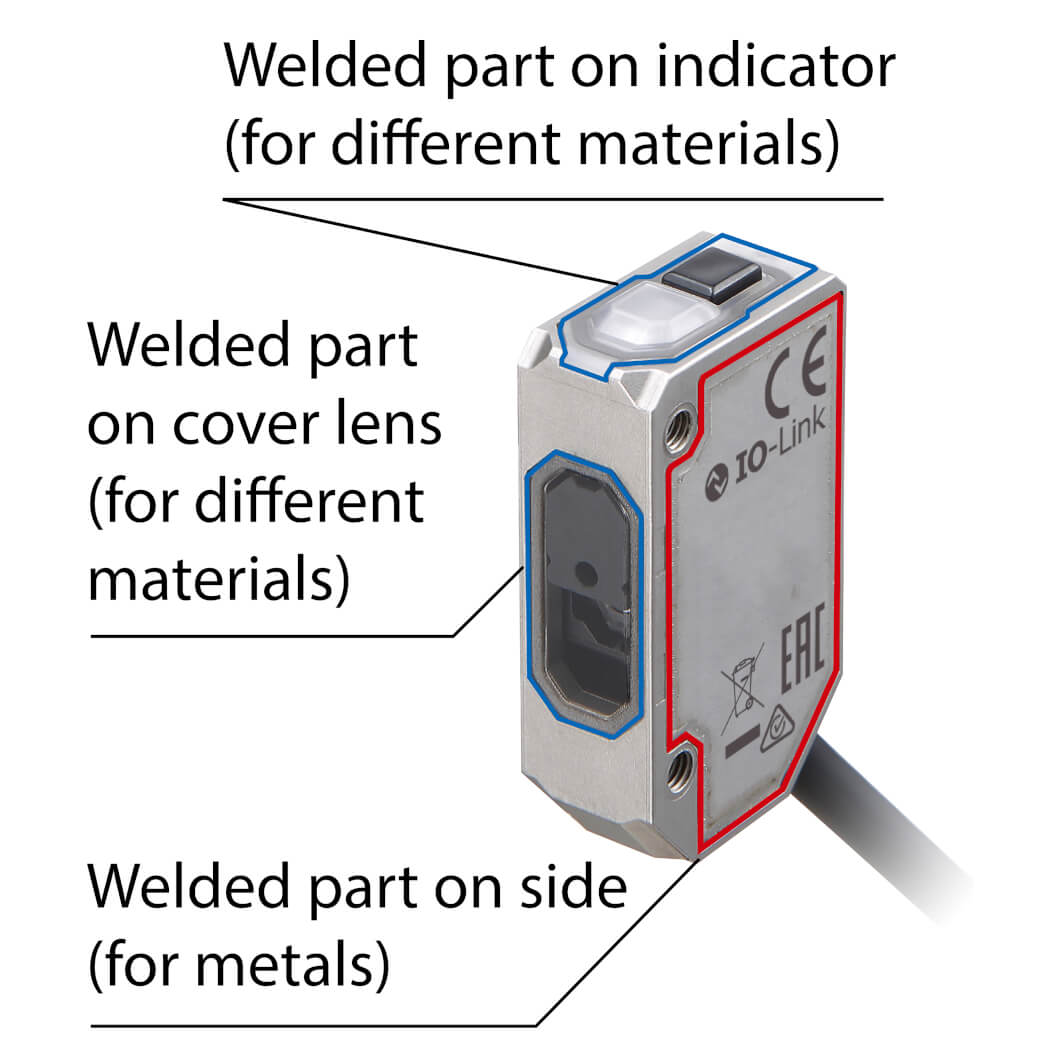

- Manufactured using OMRON's proprietary laser sealing method.

- IP67/IP69K/IP67G.

- Antifouling coatings reduce the cleaning frequency on the sensing surface.

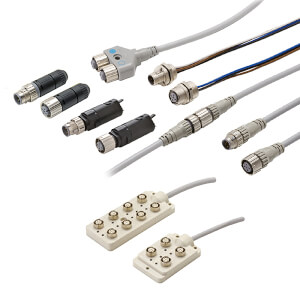

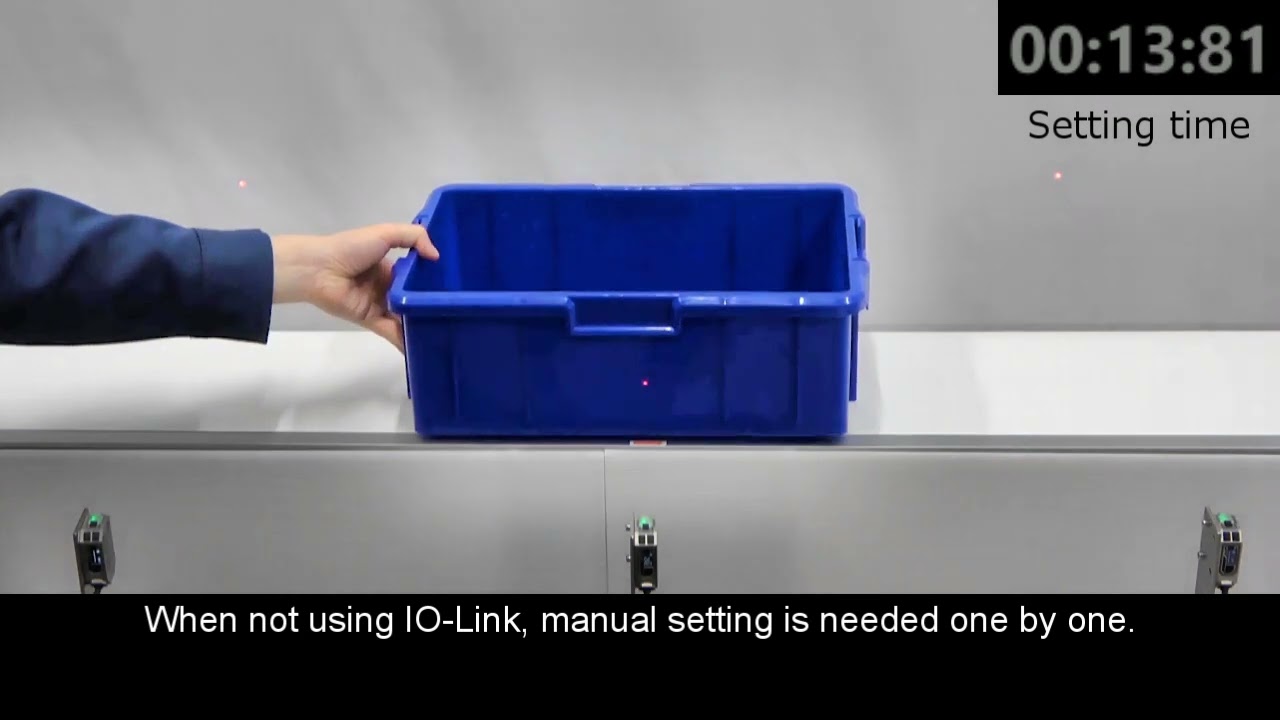

- IO-Link reduces the time required for start-ups and changeovers.

- Air blow accessory for easy maintenance.

- Equipped with OMRON's proprietary light emitting element for stable detection of low-reflective. workpieces.

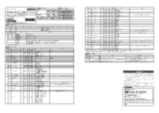

Specifications & ordering info

| Produkt | Shape | Sensing method | Sensing distance | Sensing distance (min.) | Setting method | Connection method | Cable length | Output type | Operation mode | Response time | Material housing | Type of light | Laser class | Spot size | Power supply voltage | Functions | Features | Degree of protection (IP) | Description | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

Cuboid | Background suppression | 1000 mm | 50 mm | Teach-In | Cable | 2 m | NPN | Dark-ON, Light-ON | 90 ms | Stainless steel | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | Photoelectric sensor, rectangular housing, stainless steel, infrared laser class 1, time-of-flight, 1000 mm, NPN, Light-ON/Dark-ON, 2 m cable |

|

||

|

|

Cuboid | Background suppression | 1000 mm | 50 mm | Teach-In | Connector M8 - 4 pin | NPN | Dark-ON, Light-ON | 90 ms | Stainless steel | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | Photoelectric sensor, rectangular housing, stainless steel, infrared laser class 1, time-of-flight, 1000 mm, NPN, Light-ON/Dark-ON, M8 4-pin connector |

|

|||

|

|

Cuboid | Background suppression | 1000 mm | 50 mm | Teach-In | M12 pigtail Smartclick connector | 0.3 m | NPN | Dark-ON, Light-ON | 90 ms | Stainless steel | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | Photoelectric sensor, rectangular housing, stainless steel, infrared laser class 1, time-of-flight, 1000 mm, NPN, Light-ON/Dark-ON, M12 pigtail Smartclick connector, 0.3 m |

|

||

|

|

Cuboid | Background suppression | 1000 mm | 50 mm | IO-Link, Teach-In | Cable | 2 m | IO-Link, PNP | Dark-ON, Light-ON | 90 ms | Stainless steel | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | Photoelectric sensor, rectangular housing, stainless steel, infrared laser class 1, time-of-flight, 1000 mm, PNP, Light-ON/Dark-ON, IO-Link COM3, 2 m cable |

|

||

|

|

Cuboid | Background suppression | 1000 mm | 50 mm | IO-Link, Teach-In | Connector M8 - 4 pin | IO-Link, PNP | Dark-ON, Light-ON | 90 ms | Stainless steel | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | Photoelectric sensor, rectangular housing, stainless steel, infrared laser class 1, time-of-flight, 1000 mm, PNP, Light-ON/Dark-ON, IO-Link COM3, M8 4-pin connector |

|

|||

|

|

Cuboid | Background suppression | 1000 mm | 50 mm | IO-Link, Teach-In | M12 pigtail Smartclick connector | 0.3 m | IO-Link, PNP | Dark-ON, Light-ON | 90 ms | Stainless steel | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | Photoelectric sensor, rectangular housing, stainless steel, infrared laser class 1, time-of-flight, 1000 mm, PNP, Light-ON/Dark-ON, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

||

|

|

Cuboid | Background suppression | 1000 mm | 50 mm | Teach-In | Cable | 2 m | NPN | Dark-ON, Light-ON | 90 ms | PBT | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | Photoelectric sensor, rectangular housing, plastic body, infrared laser class 1, time-of-flight, 1000 mm, NPN, Light-ON/Dark-ON, 2 m cable |

|

||

|

|

Cuboid | Background suppression | 1000 mm | 50 mm | Teach-In | Connector M8 - 4 pin | NPN | Dark-ON, Light-ON | 90 ms | PBT | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | Photoelectric sensor, rectangular housing, plastic body, infrared laser class 1, time-of-flight, 1000 mm, NPN, Light-ON/Dark-ON, M8 4-pin connector |

|

|||

|

|

Cuboid | Background suppression | 1000 mm | 50 mm | Teach-In | M12 pigtail Smartclick connector | 0.3 m | NPN | Dark-ON, Light-ON | 90 ms | PBT | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | Photoelectric sensor, rectangular housing, plastic body, infrared laser class 1, time-of-flight, 1000 mm, NPN, Light-ON/Dark-ON, M12 pigtail Smartclick connector, 0.3 m |

|

||

|

|

Cuboid | Background suppression | 1000 mm | 50 mm | IO-Link, Teach-In | Cable | 2 m | IO-Link, PNP | Dark-ON, Light-ON | 90 ms | PBT | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, plastic body, infrared laser class 1, time-of-flight, 1000 mm, PNP, Light-ON/Dark-ON, IO-Link COM3, 2 m cable |

|

|

|

|

Cuboid | Background suppression | 1000 mm | 50 mm | IO-Link, Teach-In | Cable | 5 m | IO-Link, PNP | Dark-ON, Light-ON | 90 ms | PBT | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, plastic body, infrared laser class 1, time-of-flight, 1000 mm, PNP, Light-ON/Dark-ON, IO-Link COM3, 5 m cable |

|

|

|

|

Cuboid | Background suppression | 1000 mm | 50 mm | IO-Link, Teach-In | Connector M8 - 4 pin | IO-Link, PNP | Dark-ON, Light-ON | 90 ms | PBT | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, plastic body, infrared laser class 1, time-of-flight, 1000 mm, PNP, Light-ON/Dark-ON, IO-Link COM3, M8 4-pin connector |

|

||

|

|

Cuboid | Background suppression | 1000 mm | 50 mm | IO-Link, Teach-In | M12 pigtail Smartclick connector | 0.3 m | IO-Link, PNP | Dark-ON, Light-ON | 90 ms | PBT | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, plastic body, infrared laser class 1, time-of-flight, 1000 mm, PNP, Light-ON/Dark-ON, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

|

|

|

Cuboid | Background suppression | 1000 mm | 50 mm | IO-Link, Teach-In | M8 pigtail connector 4 pin | 0.3 m | IO-Link, PNP | Dark-ON, Light-ON | 90 ms | PBT | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, plastic body, infrared laser class 1, time-of-flight, 1000 mm, PNP, Light-ON/Dark-ON, IO-Link COM3, M8 pigtail connector 4-pin, 0.3 m |

|

|

|

|

Cuboid | Background suppression | 1500 mm | 50 mm | Teach-In | Cable | 2 m | NPN | Dark-ON, Light-ON | 150 ms | Stainless steel | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, infrared laser class 1, time-of-flight, 1500 mm, NPN, Light-ON/Dark-ON, 2 m cable |

|

|

|

|

Cuboid | Background suppression | 1500 mm | 50 mm | Teach-In | Connector M8 - 4 pin | NPN | Dark-ON, Light-ON | 150 ms | Stainless steel | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | Photoelectric sensor, rectangular housing, stainless steel, infrared laser class 1, time-of-flight, 1500 mm, NPN, Light-ON/Dark-ON, M8 4-pin connector |

|

|||

|

|

Cuboid | Background suppression | 1500 mm | 50 mm | Teach-In | M12 pigtail Smartclick connector | 0.3 m | NPN | Dark-ON, Light-ON | 150 ms | Stainless steel | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | Photoelectric sensor, rectangular housing, stainless steel, infrared laser class 1, time-of-flight, 1500 mm, NPN, Light-ON/Dark-ON, M12 pigtail Smartclick connector, 0.3 m |

|

||

|

|

Cuboid | Background suppression | 1500 mm | 50 mm | IO-Link, Teach-In | Cable | 2 m | IO-Link, PNP | Dark-ON, Light-ON | 150 ms | Stainless steel | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | Photoelectric sensor, rectangular housing, stainless steel, infrared laser class 1, time-of-flight, 1500 mm, PNP, Light-ON/Dark-ON, IO-Link COM3, 2 m cable |

|

||

|

|

Cuboid | Background suppression | 1500 mm | 50 mm | IO-Link, Teach-In | Connector M8 - 4 pin | IO-Link, PNP | Dark-ON, Light-ON | 150 ms | Stainless steel | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | Photoelectric sensor, rectangular housing, stainless steel, infrared laser class 1, time-of-flight, 1500 mm, PNP, Light-ON/Dark-ON, IO-Link COM3, M8 4-pin connector |

|

|||

|

|

Cuboid | Background suppression | 1500 mm | 50 mm | IO-Link, Teach-In | M12 pigtail Smartclick connector | 0.3 m | IO-Link, PNP | Dark-ON, Light-ON | 150 ms | Stainless steel | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | Photoelectric sensor, rectangular housing, stainless steel, infrared laser class 1, time-of-flight, 1500 mm, PNP, Light-ON/Dark-ON, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

||

|

|

Cuboid | Background suppression | 1500 mm | 50 mm | Teach-In | Cable | 2 m | NPN | Dark-ON, Light-ON | 150 ms | PBT | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, plastic body, infrared laser class 1, time-of-flight, 1500 mm, NPN, Light-ON/Dark-ON, 2 m cable |

|

|

|

|

Cuboid | Background suppression | 1500 mm | 50 mm | Teach-In | Connector M8 - 4 pin | NPN | Dark-ON, Light-ON | 150 ms | PBT | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | Photoelectric sensor, rectangular housing, plastic body, infrared laser class 1, time-of-flight, 1500 mm, NPN, Light-ON/Dark-ON, M8 4-pin connector |

|

|||

|

|

Cuboid | Background suppression | 1500 mm | 50 mm | Teach-In | M12 pigtail Smartclick connector | 0.3 m | NPN | Dark-ON, Light-ON | 150 ms | PBT | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | Photoelectric sensor, rectangular housing, plastic body, infrared laser class 1, time-of-flight, 1500 mm, NPN, Light-ON/Dark-ON, M12 pigtail Smartclick connector, 0.3 m |

|

||

|

|

Cuboid | Background suppression | 1500 mm | 50 mm | IO-Link, Teach-In | Cable | 2 m | IO-Link, PNP | Dark-ON, Light-ON | 150 ms | PBT | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, plastic body, infrared laser class 1, time-of-flight, 1500 mm, PNP, Light-ON/Dark-ON, IO-Link COM3, 2 m cable |

|

|

|

|

Cuboid | Background suppression | 1500 mm | 50 mm | IO-Link, Teach-In | Cable | 5 m | IO-Link, PNP | Dark-ON, Light-ON | 150 ms | PBT | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, plastic body, infrared laser class 1, time-of-flight, 1500 mm, PNP, Light-ON/Dark-ON, IO-Link COM3, 5 m cable |

|

|

|

|

Cuboid | Background suppression | 1500 mm | 50 mm | IO-Link, Teach-In | Connector M8 - 4 pin | IO-Link, PNP | Dark-ON, Light-ON | 150 ms | PBT | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | Photoelectric sensor, rectangular housing, plastic body, infrared laser class 1, time-of-flight, 1500 mm, PNP, Light-ON/Dark-ON, IO-Link COM3, M8 4-pin connector |

|

|||

|

|

Cuboid | Background suppression | 1500 mm | 50 mm | IO-Link, Teach-In | M12 pigtail Smartclick connector | 0.3 m | IO-Link, PNP | Dark-ON, Light-ON | 150 ms | PBT | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | Photoelectric sensor, rectangular housing, plastic body, infrared laser class 1, time-of-flight, 1500 mm, PNP, Light-ON/Dark-ON, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

||

|

|

Cuboid | Background suppression | 1500 mm | 50 mm | IO-Link, Teach-In | M8 pigtail connector 4 pin | 0.3 m | IO-Link, PNP | Dark-ON, Light-ON | 150 ms | PBT | Laser diode, infrared light | 1 | 95 mm | 10-30 V | TOF (Time of Flight) | Photoelectric sensor, rectangular housing, plastic body, infrared laser class 1, time-of-flight, 1500 mm, PNP, Light-ON/Dark-ON, IO-Link COM3, M8 pigtail connector 4-pin, 0.3 m |

|

||

|

|

Cuboid | Background suppression | 150 mm | 35 mm | Teach-In | Cable | 2 m | NPN | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 8 mm x 1.3 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, line beam, 35-150 mm, 10-30 VDC, NPN, Light-ON/Dark-ON, 2 m cable |

|

||

|

|

Cuboid | Background suppression | 150 mm | 35 mm | Teach-In | Connector M8 - 4 pin | NPN | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 8 mm x 1.3 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, line beam, 35-150 mm, 10-30 VDC, NPN, Light-ON/Dark-ON, M8 connector 4-pin |

|

|||

|

|

Cuboid | Background suppression | 150 mm | 35 mm | Teach-In | M12 pigtail Smartclick connector | 0.3 m | NPN | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 8 mm x 1.3 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, line beam, 35-150 mm, 10-30 VDC, NPN, Light-ON/Dark-ON, M12 pigtail Smartclick connector, 0.3 m |

|

||

|

|

Cuboid | Background suppression | 150 mm | 35 mm | IO-Link, Teach-In | Cable | 2 m | IO-Link, PNP | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 8 mm x 1.3 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, line beam, 35-150 mm, 10-30 VDC, PNP, Light-ON/Dark-ON, IO-Link COM3, 2 m cable |

|

||

|

|

Cuboid | Background suppression | 150 mm | 35 mm | IO-Link, Teach-In | Cable | 5 m | IO-Link, PNP | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 8 mm x 1.3 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, line beam, 35-150 mm, 10-30 VDC, PNP, Light-ON/Dark-ON, IO-Link COM3, 5 m cable |

|

||

|

|

Cuboid | Background suppression | 150 mm | 35 mm | IO-Link, Teach-In | Connector M8 - 4 pin | IO-Link, PNP | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 8 mm x 1.3 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, line beam, 35-150 mm, 10-30 VDC, PNP, Light-ON/Dark-ON, IO-Link COM3, M8 connector 4-pin |

|

|||

|

|

Cuboid | Background suppression | 150 mm | 35 mm | IO-Link, Teach-In | M12 pigtail Smartclick connector | 0.3 m | IO-Link, PNP | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 8 mm x 1.3 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, line beam, 35-150 mm, 10-30 VDC, PNP, Light-ON/Dark-ON, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

||

|

|

Cuboid | Background suppression | 150 mm | 35 mm | IO-Link, Teach-In | M8 pigtail connector 4 pin | 0.3 m | IO-Link, PNP | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 8 mm x 1.3 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, line beam, 35-150 mm, 10-30 VDC, PNP, Light-ON/Dark-ON, IO-Link COM3, M8 pigtail connector 4-pin, 0.3 m |

|

||

|

|

Cuboid | Background suppression | 150 mm | 35 mm | Teach-In | Cable | 2 m | NPN | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 2.5 mm x 1.3 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, spot beam, 35-150 mm, 10-30 VDC, NPN, Light-ON/Dark-ON, 2 m cable |

|

||

|

|

Cuboid | Background suppression | 150 mm | 35 mm | Teach-In | Connector M8 - 4 pin | NPN | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 2.5 mm x 1.3 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, spot beam, 35-150 mm, 10-30 VDC, NPN, Light-ON/Dark-ON, M8 connector 4-pin |

|

|||

|

|

Cuboid | Background suppression | 150 mm | 35 mm | Teach-In | M12 pigtail Smartclick connector | 0.3 m | NPN | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 2.5 mm x 1.3 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, spot beam, 35-150 mm, 10-30 VDC, NPN, Light-ON/Dark-ON, M12 pigtail Smartclick connector, 0.3 m |

|

||

|

|

Cuboid | Background suppression | 150 mm | 35 mm | IO-Link, Teach-In | Cable | 2 m | IO-Link, PNP | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 2.5 mm x 1.3 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, spot beam, 35-150 mm, 10-30 VDC, PNP, Light-ON/Dark-ON, IO-Link COM3, 2 m cable |

|

||

|

|

Cuboid | Background suppression | 150 mm | 35 mm | IO-Link, Teach-In | Cable | 5 m | IO-Link, PNP | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 2.5 mm x 1.3 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, spot beam, 35-150 mm, 10-30 VDC, PNP, Light-ON/Dark-ON, IO-Link COM3, 5 m cable |

|

||

|

|

Cuboid | Background suppression | 150 mm | 35 mm | IO-Link, Teach-In | Connector M8 - 4 pin | IO-Link, PNP | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 2.5 mm x 1.3 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, spot beam, 35-150 mm, 10-30 VDC, PNP, Light-ON/Dark-ON, IO-Link COM3, M8 connector 4-pin |

|

|||

|

|

Cuboid | Background suppression | 150 mm | 35 mm | IO-Link, Teach-In | M12 pigtail Smartclick connector | 0.3 m | IO-Link, PNP | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 2.5 mm x 1.3 mm | 10-30 V | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, spot beam, 35-150 mm, 10-30 VDC, PNP, Light-ON/Dark-ON, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

|||

|

|

Cuboid | Background suppression | 150 mm | 35 mm | IO-Link, Teach-In | M8 pigtail connector 4 pin | 0.3 m | IO-Link, PNP | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 2.5 mm x 1.3 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, spot beam, 35-150 mm, 10-30 VDC, PNP, Light-ON/Dark-ON, IO-Link COM3, M8 pigtail connector 4-pin, 0.3 m |

|

||

|

|

Cuboid | Background suppression | 500 mm | 35 mm | Teach-In | Cable | 2 m | NPN | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 18 mm x 1.5 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, line beam, 35-500 mm, 10-30 VDC, NPN, Light-ON/Dark-ON, 2 m cable |

|

||

|

|

Cuboid | Background suppression | 500 mm | 35 mm | Teach-In | Connector M8 - 4 pin | NPN | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 18 mm x 1.5 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, line beam, 35-500 mm, 10-30 VDC, NPN, Light-ON/Dark-ON, M8 connector 4-pin |

|

|||

|

|

Cuboid | Background suppression | 500 mm | 35 mm | Teach-In | M12 pigtail Smartclick connector | 0.3 m | NPN | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 18 mm x 1.5 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, line beam, 35-500 mm, 10-30 VDC, NPN, Light-ON/Dark-ON, M12 pigtail Smartclick connector, 0.3 m |

|

||

|

|

Cuboid | Background suppression | 500 mm | 35 mm | IO-Link, Teach-In | Cable | 2 m | IO-Link, PNP | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 18 mm x 1.5 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, line beam, 35-500 mm, 10-30 VDC, PNP, Light-ON/Dark-ON, IO-Link COM3, 2 m cable |

|

||

|

|

Cuboid | Background suppression | 500 mm | 35 mm | IO-Link, Teach-In | Cable | 5 m | IO-Link, PNP | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 18 mm x 1.5 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, line beam, 35-500 mm, 10-30 VDC, PNP, Light-ON/Dark-ON, IO-Link COM3, 5 m cable |

|

||

|

|

Cuboid | Background suppression | 500 mm | 35 mm | IO-Link, Teach-In | Connector M8 - 4 pin | IO-Link, PNP | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 18 mm x 1.5 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, line beam, 35-500 mm, 10-30 VDC, PNP, Light-ON/Dark-ON, IO-Link COM3, M8 connector 4-pin |

|

|||

|

|

Cuboid | Background suppression | 500 mm | 35 mm | IO-Link, Teach-In | M12 pigtail Smartclick connector | 0.3 m | IO-Link, PNP | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 18 mm x 1.5 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, line beam, 35-500 mm, 10-30 VDC, PNP, Light-ON/Dark-ON, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

||

|

|

Cuboid | Background suppression | 500 mm | 35 mm | IO-Link, Teach-In | M8 pigtail connector 4 pin | 0.3 m | IO-Link, PNP | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 18 mm x 1.5 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, line beam, 35-500 mm, 10-30 VDC, PNP, Light-ON/Dark-ON, IO-Link COM3, M8 pigtail connector 4-pin, 0.3 m |

|

||

|

|

Cuboid | Background suppression | 500 mm | 35 mm | Teach-In | Cable | 2 m | NPN | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 2.5 mm x 1.5 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, spot beam, 35-500 mm, 10-30 VDC, NPN, Light-ON/Dark-ON, 2 m cable |

|

||

|

|

Cuboid | Background suppression | 500 mm | 35 mm | Teach-In | Connector M8 - 4 pin | NPN | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 2.5 mm x 1.5 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, spot beam, 35-500 mm, 10-30 VDC, NPN, Light-ON/Dark-ON, M8 connector 4-pin |

|

|||

|

|

Cuboid | Background suppression | 500 mm | 35 mm | Teach-In | M12 pigtail Smartclick connector | 0.3 m | NPN | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 2.5 mm x 1.5 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, spot beam, 35-500 mm, 10-30 VDC, NPN, Light-ON/Dark-ON, M12 pigtail Smartclick connector, 0.3 m |

|

||

|

|

Cuboid | Background suppression | 500 mm | 35 mm | IO-Link, Teach-In | Cable | 2 m | IO-Link, PNP | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 2.5 mm x 1.5 mm | 10-30 V | Timer | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, spot beam, 35-500 mm, 10-30 VDC, PNP, Light-ON/Dark-ON, IO-Link COM3, 2 m cable |

|

|

|

|

Cuboid | Background suppression | 500 mm | 35 mm | IO-Link, Teach-In | Cable | 5 m | IO-Link, PNP | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 2.5 mm x 1.5 mm | 10-30 V | Timer | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, spot beam, 35-500 mm, 10-30 VDC, PNP, Light-ON/Dark-ON, IO-Link COM3, 5 m cable |

|

|

|

|

Cuboid | Background suppression | 500 mm | 35 mm | IO-Link, Teach-In | Connector M8 - 4 pin | IO-Link, PNP | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 2.5 mm x 1.5 mm | 10-30 V | Timer | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, spot beam, 35-500 mm, 10-30 VDC, PNP, Light-ON/Dark-ON, IO-Link COM3, M8 connector 4-pin |

|

||

|

|

Cuboid | Background suppression | 500 mm | 35 mm | IO-Link, Teach-In | M12 pigtail Smartclick connector | 0.3 m | IO-Link, PNP | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 2.5 mm x 1.5 mm | 10-30 V | Timer | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, spot beam, 35-500 mm, 10-30 VDC, PNP, Light-ON/Dark-ON, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

|

|

|

Cuboid | Background suppression | 500 mm | 35 mm | IO-Link, Teach-In | M8 pigtail connector 4 pin | 0.3 m | IO-Link, PNP | Dark-ON, Light-ON | 1.5 ms | Stainless steel | Laser diode, red light | 1 | 2.5 mm x 1.5 mm | 10-30 V | Timer | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red laser class 1, background suppression, spot beam, 35-500 mm, 10-30 VDC, PNP, Light-ON/Dark-ON, IO-Link COM3, M8 pigtail connector 4-pin, 0.3 m |

|

|

|

|

Cuboid | Background suppression | 200 mm | 10 mm | Teach-In | Cable | 2 m | NPN | Dark-ON, Light-ON | 1 ms | Stainless steel | Polarity free red light | 25 x 25 mm | 10-30 V | IP67/IP67G/IP69K | Photoelectric sensor, rectangular housing, stainless steel, red LED, background suppression, 200 mm, NPN, Light-ON/Dark-ON, 2 m cable |

|

|||

|

|

Cuboid | Background suppression | 200 mm | 10 mm | Teach-In | Connector M8 - 4 pin | NPN | Dark-ON, Light-ON | 1 ms | Stainless steel | Polarity free red light | 25 x 25 mm | 10-30 V | Photoelectric sensor, rectangular housing, stainless steel, red LED, background suppression, 200 mm, NPN, Light-ON/Dark-ON, M8 4-pin connector |

|

|||||

|

|

Cuboid | Background suppression | 200 mm | 10 mm | Teach-In | M12 pigtail Smartclick connector | 0.3 m | NPN | Dark-ON, Light-ON | 1 ms | Stainless steel | Polarity free red light | 25 x 25 mm | 10-30 V | Photoelectric sensor, rectangular housing, stainless steel, red LED, background suppression, 200 mm, NPN, Light-ON/Dark-ON, M12 pigtail Smartclick connector, 0.3 m |

|

||||

|

|

Cuboid | Background suppression | 200 mm | 10 mm | IO-Link, Teach-In | Cable | 2 m | IO-Link, PNP | Dark-ON, Light-ON | 1 ms | Stainless steel | Polarity free red light | 25 x 25 mm | 10-30 V | Photoelectric sensor, rectangular housing, stainless steel, red LED, background suppression, 200 mm, PNP, Light-ON/Dark-ON, IO-Link COM3, 2 m cable |

|

||||

|

|

Cuboid | Background suppression | 200 mm | 10 mm | IO-Link, Teach-In | Connector M8 - 4 pin | IO-Link, PNP | Dark-ON, Light-ON | 1 ms | Stainless steel | Polarity free red light | 25 x 25 mm | 10-30 V | Photoelectric sensor, rectangular housing, stainless steel, red LED, background suppression, 200 mm, PNP, Light-ON/Dark-ON, IO-Link COM3, M8 4-pin connector |

|

|||||

|

|

Cuboid | Background suppression | 200 mm | 10 mm | IO-Link, Teach-In | M12 pigtail Smartclick connector | 0.3 m | IO-Link, PNP | Dark-ON, Light-ON | 1 ms | Stainless steel | Polarity free red light | 25 x 25 mm | 10-30 V | Photoelectric sensor, rectangular housing, stainless steel, red LED, background suppression, 200 mm, PNP, Light-ON/Dark-ON, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

||||

|

|

Cuboid | Background suppression | 80 mm | 10 mm | Teach-In | Cable | 2 m | NPN | Dark-ON, Light-ON | 1 ms | Stainless steel | Polarity free red light | 4 mm | 10-30 V | Photoelectric sensor, rectangular housing, stainless steel, red LED, background suppression, 80 mm, NPN, Light-ON/Dark-ON, 2 m cable |

|

||||

|

|

Cuboid | Background suppression | 80 mm | 10 mm | Teach-In | Connector M8 - 4 pin | NPN | Dark-ON, Light-ON | 1 ms | Stainless steel | Polarity free red light | 4 mm | 10-30 V | Photoelectric sensor, rectangular housing, stainless steel, red LED, background suppression, 80 mm, NPN, Light-ON/Dark-ON, M8 4-pin connector |

|

|||||

|

|

Cuboid | Background suppression | 80 mm | 10 mm | Teach-In | M12 pigtail Smartclick connector | 0.3 m | NPN | Dark-ON, Light-ON | 1 ms | Stainless steel | Polarity free red light | 4 mm | 10-30 V | Photoelectric sensor, rectangular housing, stainless steel, red LED, background suppression, 80 mm, NPN, Light-ON/Dark-ON, M12 pigtail Smartclick connector, 0.3 m |

|

||||

|

|

Cuboid | Background suppression | 80 mm | 10 mm | IO-Link, Teach-In | Cable | 2 m | IO-Link, PNP | Dark-ON, Light-ON | 1 ms | Stainless steel | Polarity free red light | 4 mm | 10-30 V | Photoelectric sensor, rectangular housing, stainless steel, red LED, background suppression, 80 mm, PNP, Light-ON/Dark-ON, IO-Link COM3, 2 m cable |

|

||||

|

|

Cuboid | Background suppression | 80 mm | 10 mm | IO-Link, Teach-In | Connector M8 - 4 pin | IO-Link, PNP | Dark-ON, Light-ON | 1 ms | Stainless steel | Polarity free red light | 4 mm | 10-30 V | Photoelectric sensor, rectangular housing, stainless steel, red LED, background suppression, 80 mm, PNP, Light-ON/Dark-ON, IO-Link COM3, M8 4-pin connector |

|

|||||

|

|

Cuboid | Background suppression | 80 mm | 10 mm | IO-Link, Teach-In | M12 pigtail Smartclick connector | 0.3 m | IO-Link, PNP | Dark-ON, Light-ON | 1 ms | Stainless steel | Polarity free red light | 4 mm | 10-30 V | Photoelectric sensor, rectangular housing, stainless steel, red LED, background suppression, 80 mm, PNP, Light-ON/Dark-ON, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

How can we help you?

If you have a question or would like to ask for a quote, please contact us or send a request.

Kontakta mig E3AS

Tack för din förfrågan. Vi återkommer inom kort.

Vi har tekniska problem. Din formulär har inte varit framgångsrik. Vi ber om ursäkt och försök igen senare.

DownloadOffert för E3AS

Fyll i alla obligatoriska fält. Vänligen fyll i alla fält markerade med *. Dina personliga uppgifter behandlas konfidentiellt.

Tack för din offertförfrågan. Vi återkommer med önskad information inom kort.

Vi har tekniska problem. Din formulär har inte varit framgångsrik. Vi ber om ursäkt och försök igen senare.

DownloadFeatures

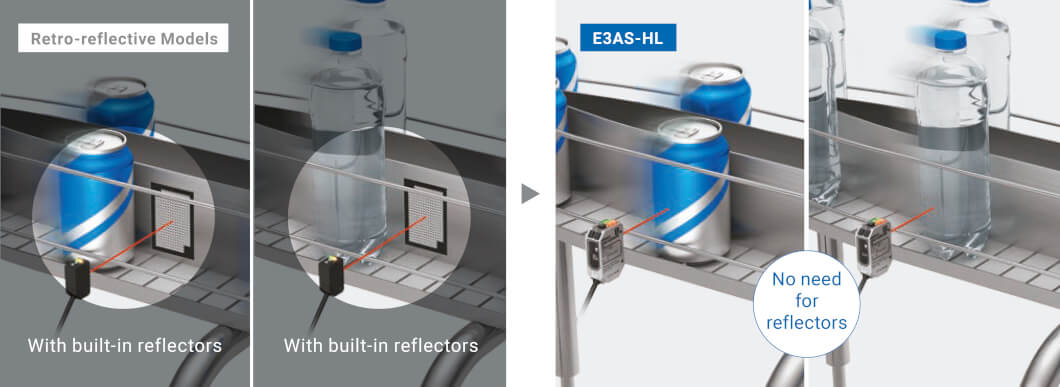

Stably detects cans and plastic bottles without reflectors

Left image: Retro-reflective sensors are used to detect poorly reflective curved surfaces of cans and transparent plastic bottles, but securing installation space for reflectors on multi-lane conveyor lines is difficult.

Right image: The E3AS-HL Sensor, a reflective model capable of detecting the slightest change in the incident light level or distance, can stably detect cans and plastic bottles without reflectors.

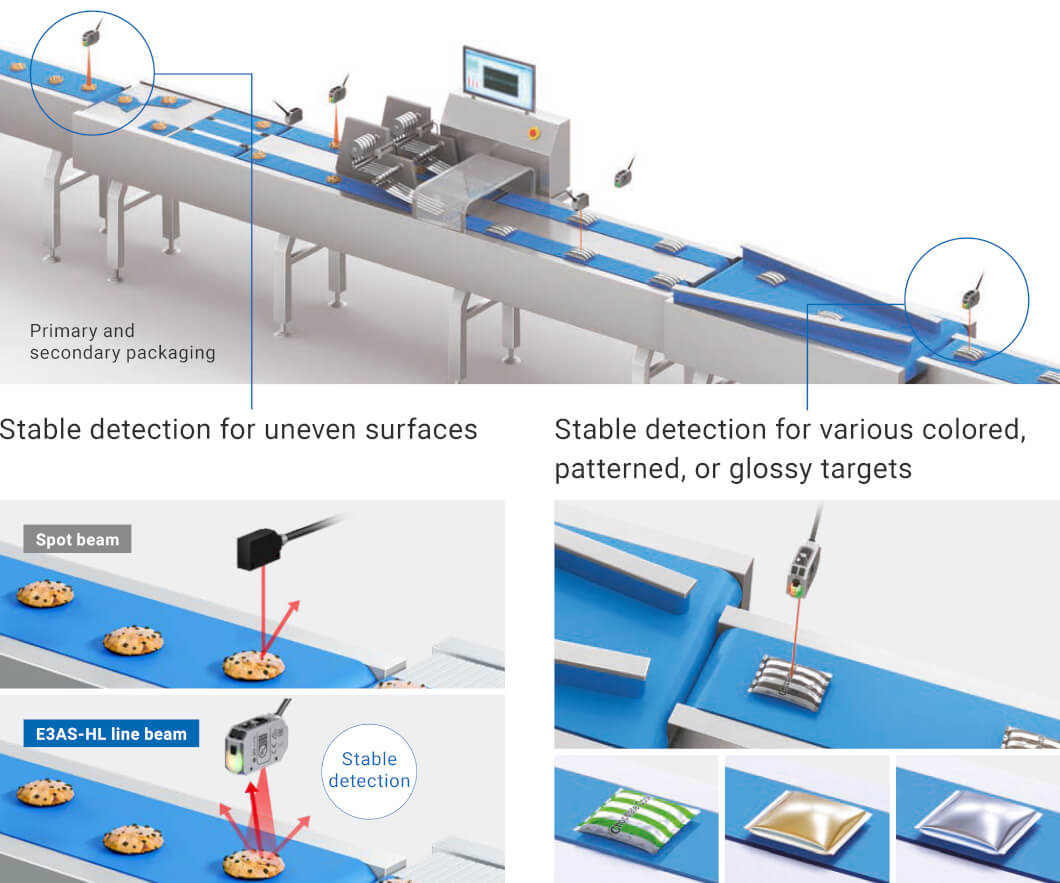

E3AS-HL for complex-shaped, colored, patterned or glossy targets

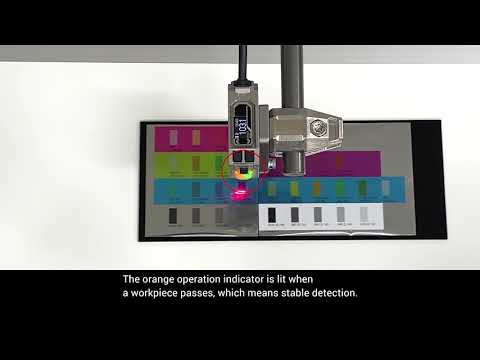

Left image: With spot beam, detection is unstable since the reflected light does not reach the sensor depending on the profile of the target surface. With the line beam of the E3AS-HL Sensor, detection is less affected by the profile of the surface since the reflected light reaches the sensor from any part of the surface.

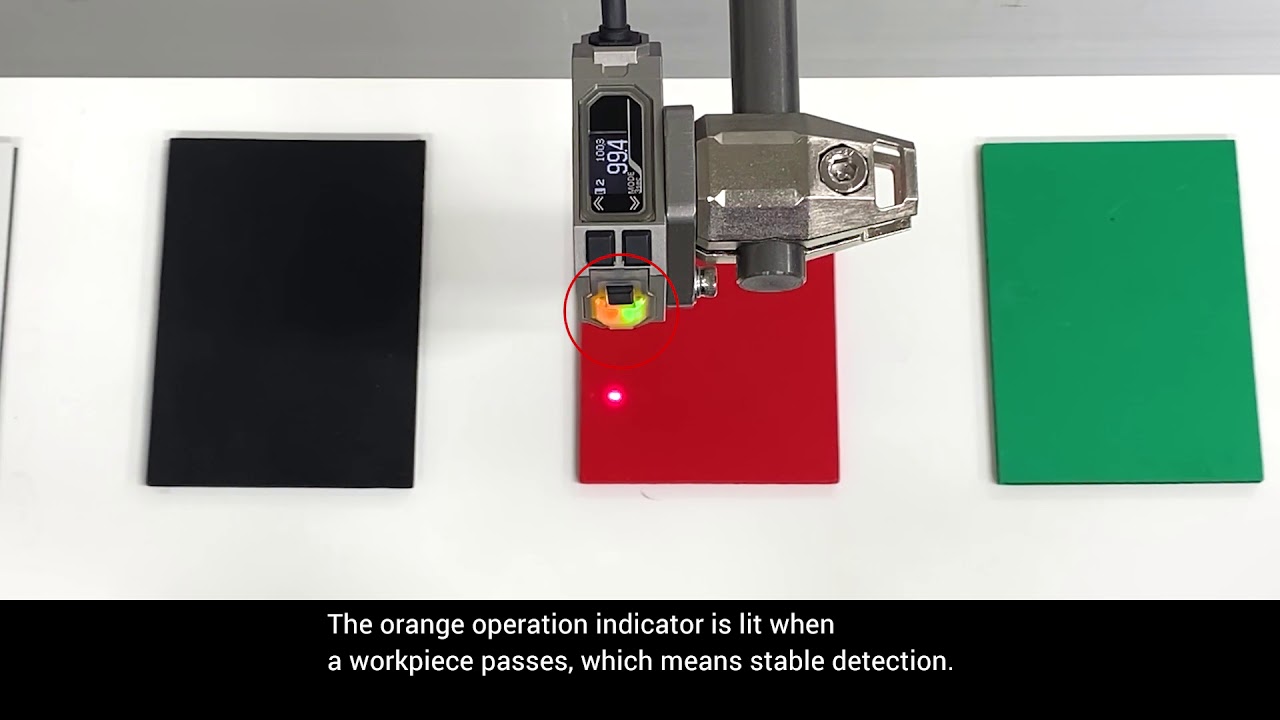

Right image: Detection is prone to be unstable because color, pattern or reflectivity affects the sensing distance. The E3AS-HL Sensor is less likely to be affected by them, providing stable detection even when packaging materials change.

E3AS-F for long-distance sensing on converging and diverging lines

No reflector is required to design long-distance sensing unaffected by color or material of targets

Although retro-reflective sensors are used for long-distance sensing in converging and diverging lines, it is difficult to find installation space for reflectors.

The E3AS-HL Sensor, a reflective model with long sensing distance, does not require reflectors. Moreover, it is less likely to be affected by color even from long distances.

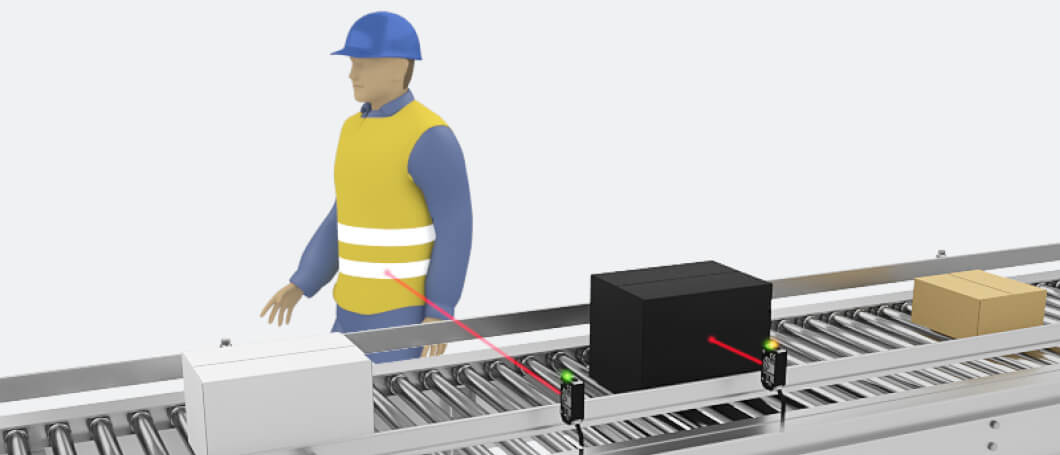

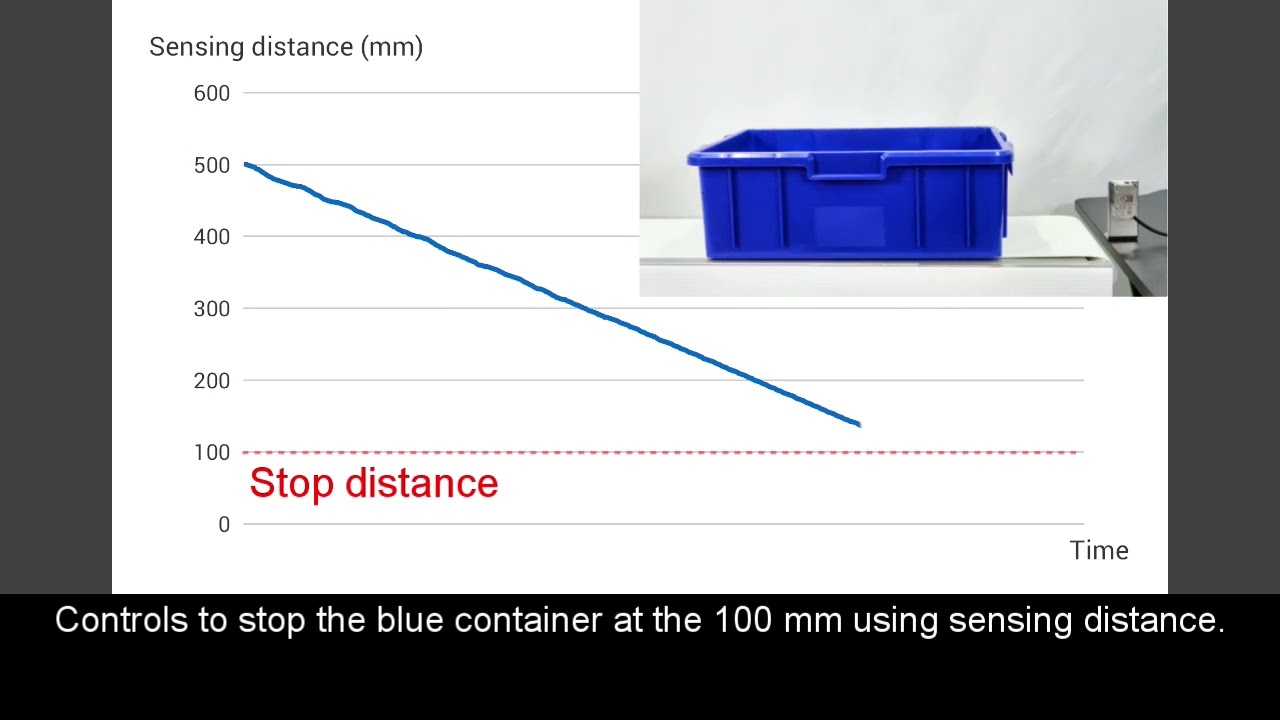

TOF method enables detection of various workpieces on the conveyor line

With conventional photoelectric sensors, prior evaluation was required for each workpiece to be detected. E3AS-F Sensors detect workpieces varying in colors and materials by the set distance. This helps reduce evaluation and adjustment time. Also, they do not detect workers working near the line by mistake.

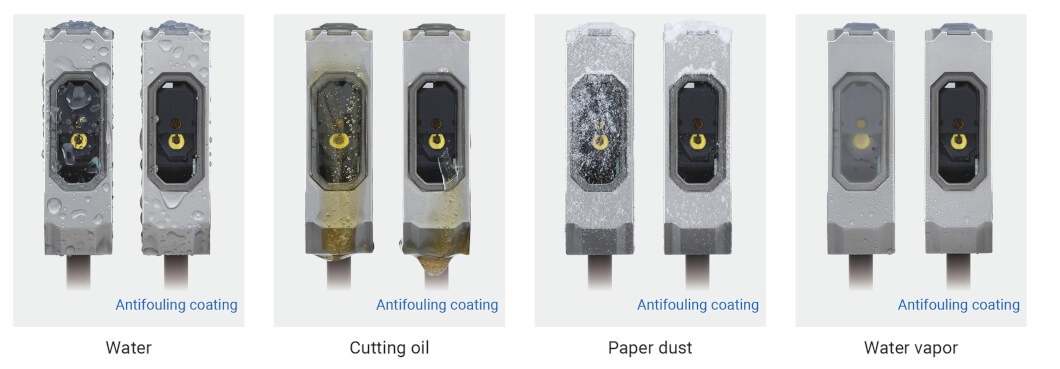

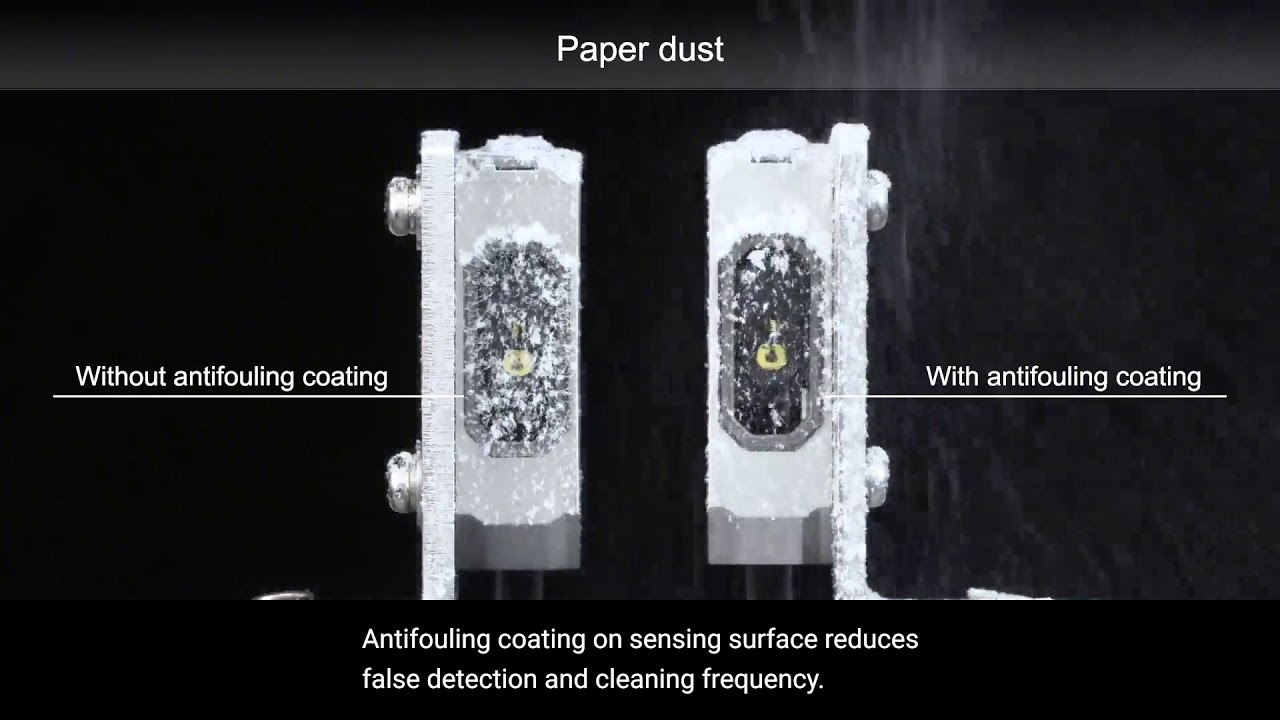

Antifouling coating prevents contamination on the sensing surface

Dirty sensing surface can cause false detection due to the principle of photoelectric sensors. E3AS Series with the antifouling coating on the sensing surface, which is the industry's first, prevents water droplets, oil, and dust from sticking to the sensing surface, and keeps the lens from fogging as well. Therefore, the coating prevents contamination on the sensing surface in environments where oil or dust scatters, or steam generates. False detection and cleaning frequency are also reduced.

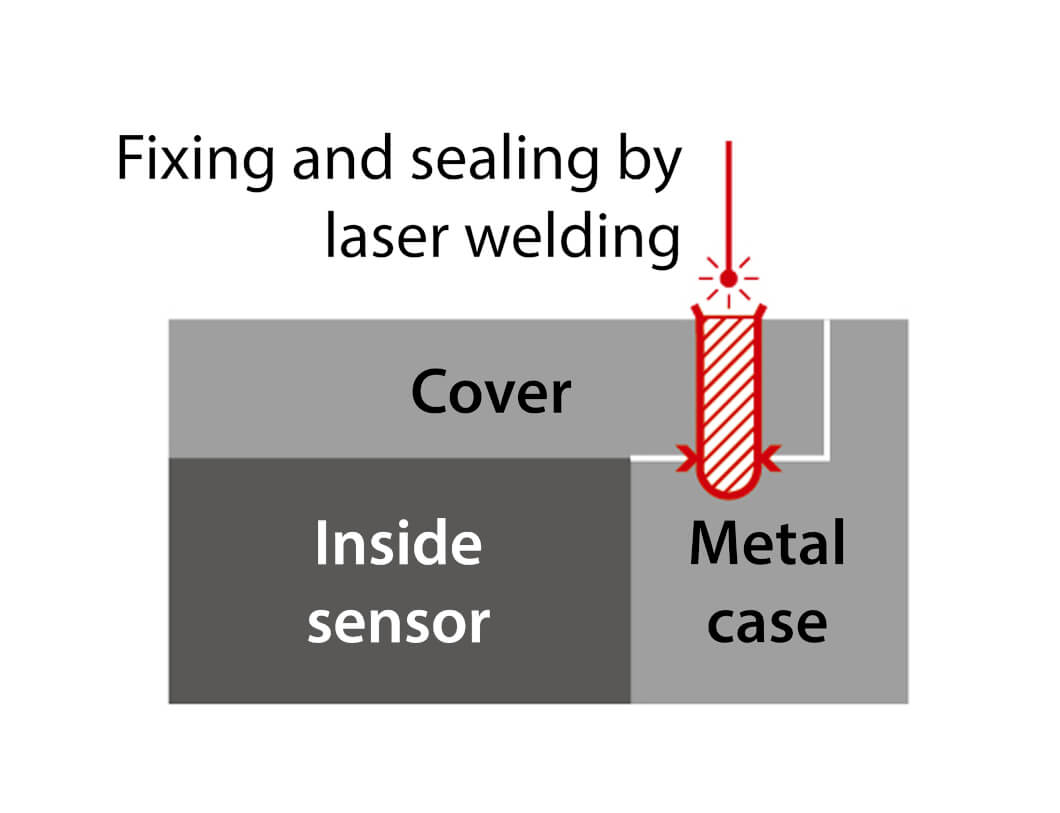

Laser welding technologies for different materials/metals for increased environmental resistance

The sensor case is made of stainless steel (SUS316L). Omron's two unique technologies, laser welding technology for different materials and laser welding technology for metals, enhanced the sealing and adhesion between the stainless steel and resin.

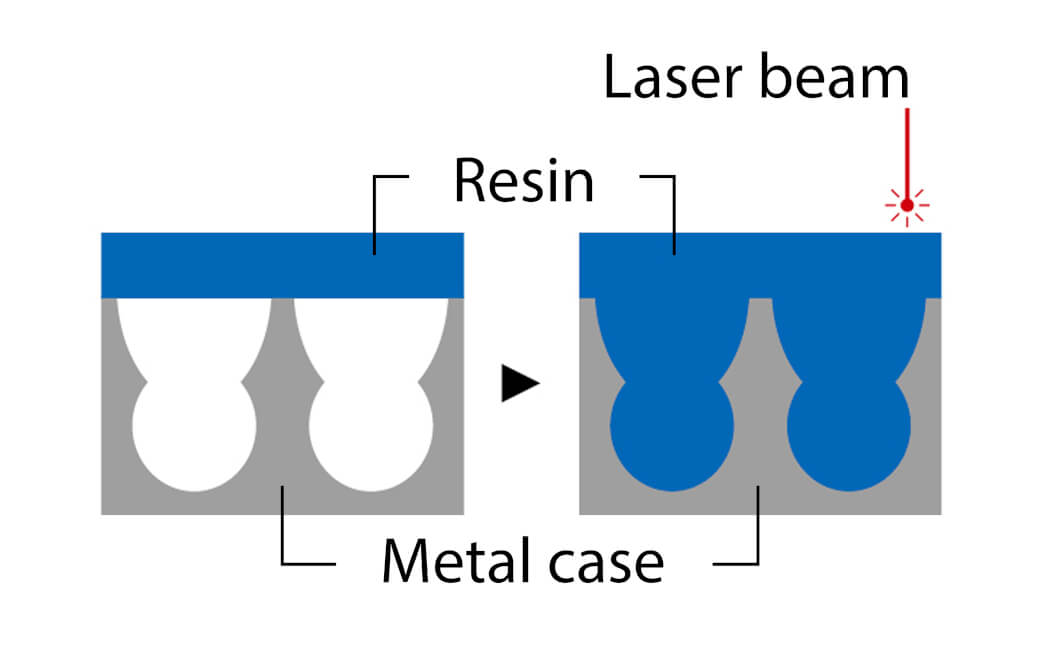

Laser welding technology for different materials

It is a technology to weld different materials, resin and metal, using laser beams. Small holes are bored into the metal case, then melt the resin part by laser. The melted resin fills the holes for secure sealing and adhesion.

Videos

-

Look inside the E3AS photoelectric sensor: 3D blowout video

OMRON's E3AS advanced reflective photoelectric sensors are ideal for quick and easy equipment design and commissioning. Take a look inside for the detailed features, and read more here:

00:39

Look inside the E3AS photoelectric sensor: 3D blowout video

OMRON's E3AS advanced reflective photoelectric sensors are ideal for quick and easy equipment design and commissioning. Take a look inside for the detailed features, and read more here:

Omron E3AS Photoelectric Sensors | Easy selection for any application

-

OMRON E3AS Photoelectric Sensors | Flexible to design for Food Industry without reflectors.

E3AS-HL CMOS sensor for multi-lane conveyor lines of workpieces with curved surfaces, with sensing distance up to 500mm.

01:58

OMRON E3AS Photoelectric Sensors | Flexible to design for Food Industry without reflectors.

E3AS-HL CMOS sensor for multi-lane conveyor lines of workpieces with curved surfaces, with sensing distance up to 500mm.

Easy to commissioning and maintenance for Food Industry with E3AS Sensors from OMRON

Application video

-

OMRON E3AS Predictive maintenance by using incident light level

Predictive maintenance example thanks to OMRON Air-blow accessory and IO-LINK #MakeitOMRON #industrialautomation

00:32

OMRON E3AS Predictive maintenance by using incident light level

Predictive maintenance example thanks to OMRON Air-blow accessory and IO-LINK #MakeitOMRON #industrialautomation

-

OMRON E3AS Control the stop position of workpiece by using detection value output

OMRON E3AS Position control through IO-LINK #MakeitOMRON #industrialautomation

00:45

OMRON E3AS Control the stop position of workpiece by using detection value output

OMRON E3AS Position control through IO-LINK #MakeitOMRON #industrialautomation

-

OMRON E3AS Shortening the setting time by setting the threshold value

OMRON E3AS fast commissioning through IO-LINK #MakeitOMRON #industrialautomation

01:04

OMRON E3AS Shortening the setting time by setting the threshold value

OMRON E3AS fast commissioning through IO-LINK #MakeitOMRON #industrialautomation