K7TM-A2

Electric Heaters Condition Monitoring Device

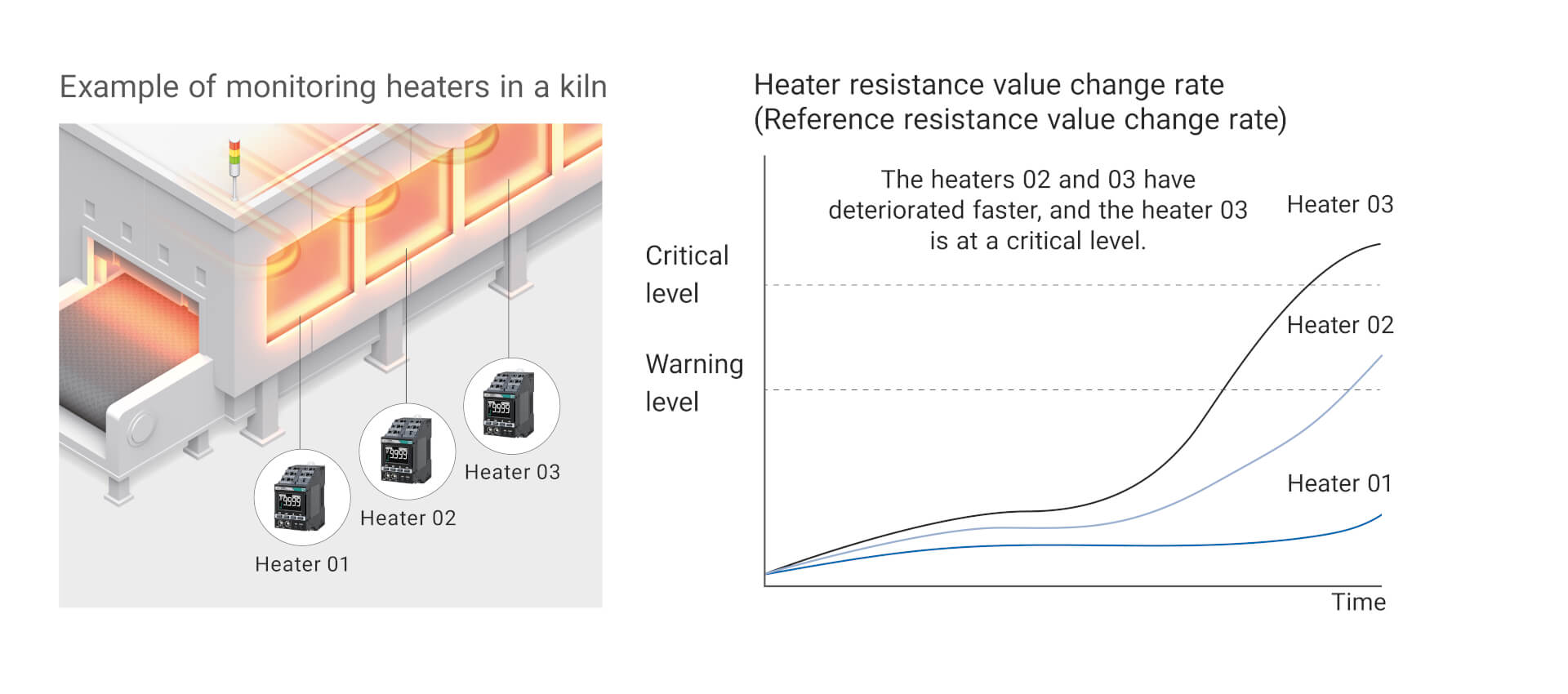

K7TM-A2 monitors the degradation of electrical heaters, avoiding costly unplanned downtime due to heaters’ failure and allowing to plan their replacement before their degradation negatively impact the quality of products and process.

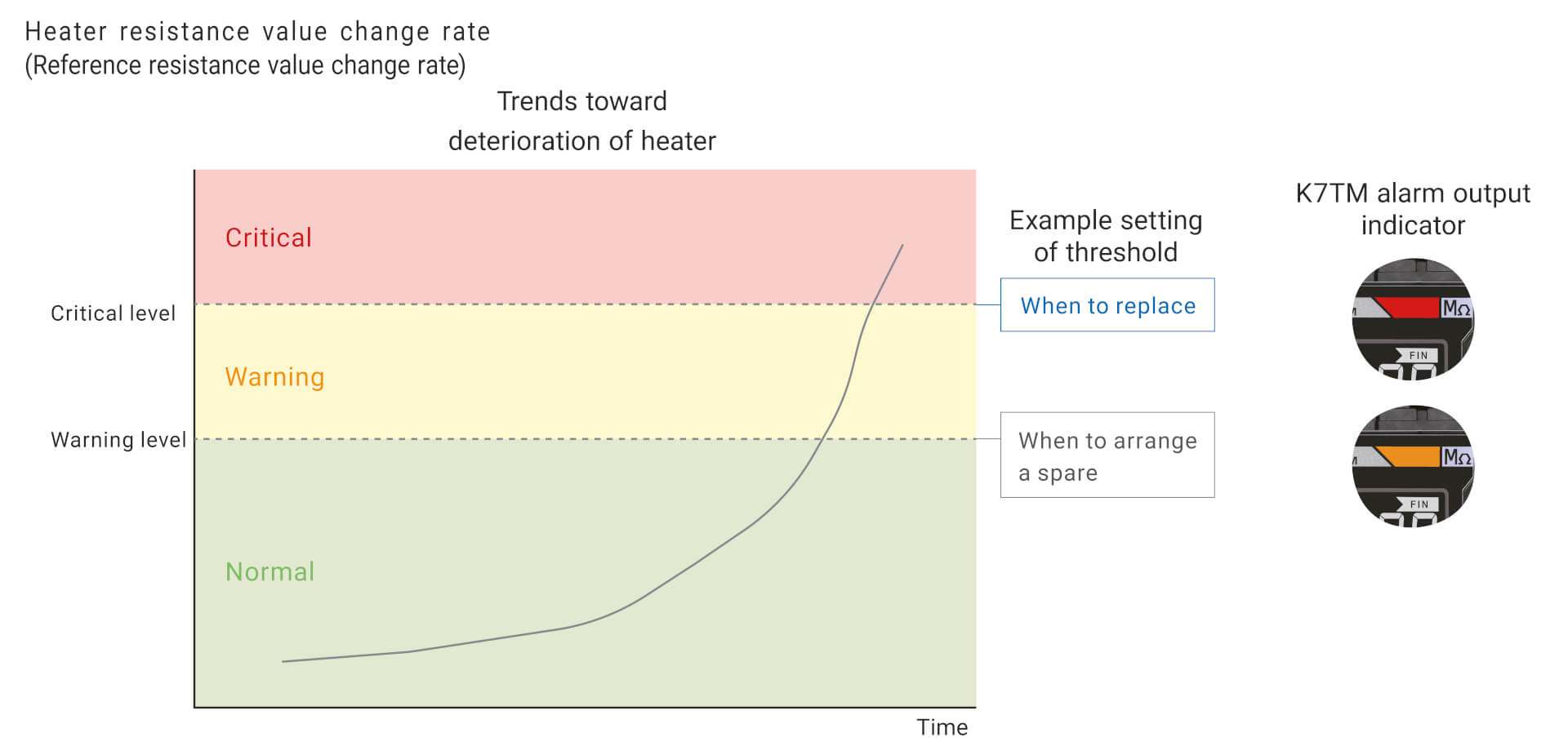

- Automatic measurement of the heating degradation during operation, triggering warnings and alarms are triggered when a certain threshold is reached.

- Easy retrofit of existing machinery (all in panel)

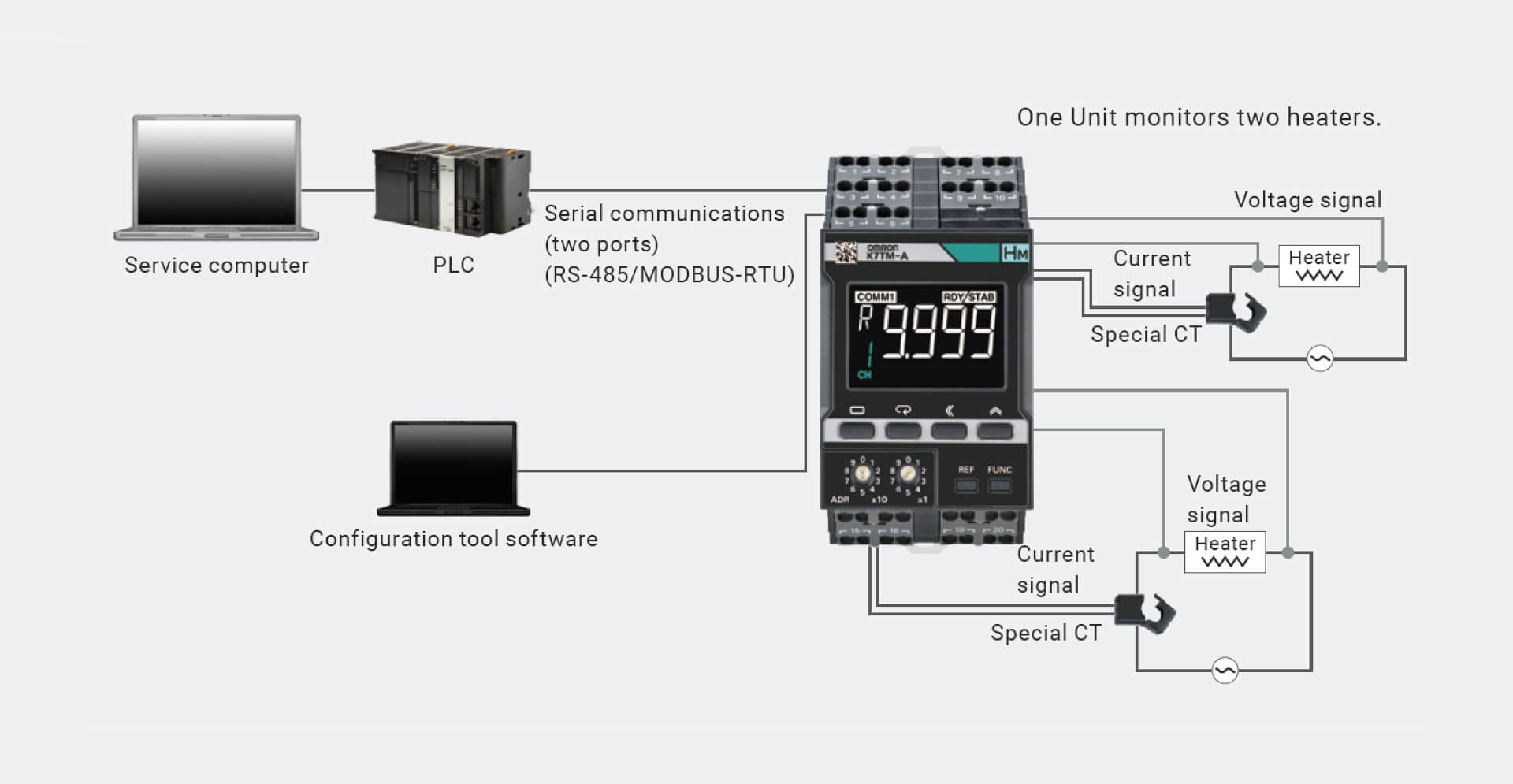

- Usable either as stand alone device or connected to a PLC

Specifications & ordering info

| Produkt | Supply voltage AC | Supply voltage DC | Description | |

|---|---|---|---|---|

|

|

100-240 V | Heater resistance monitoring device, 100 to 240 VAC, transistor control output, Push-in Plus, LCD display, RS-485/Modbus/RTU |

|

|

|

|

20.4-26.4 V | 20.4-26.4 V | Heater resistance monitoring device, 24 VAC/VDC, transistor control output, Push-in Plus, LCD display, RS-485/Modbus/RTU |

|

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Kontakta mig K7TM-A2

Tack för din förfrågan. Vi återkommer inom kort.

Vi har tekniska problem. Din formulär har inte varit framgångsrik. Vi ber om ursäkt och försök igen senare.

DownloadOffert för K7TM-A2

Fyll i alla obligatoriska fält. Vänligen fyll i alla fält markerade med *. Dina personliga uppgifter behandlas konfidentiellt.

Tack för din offertförfrågan. Vi återkommer med önskad information inom kort.

Vi har tekniska problem. Din formulär har inte varit framgångsrik. Vi ber om ursäkt och försök igen senare.

DownloadFeatures

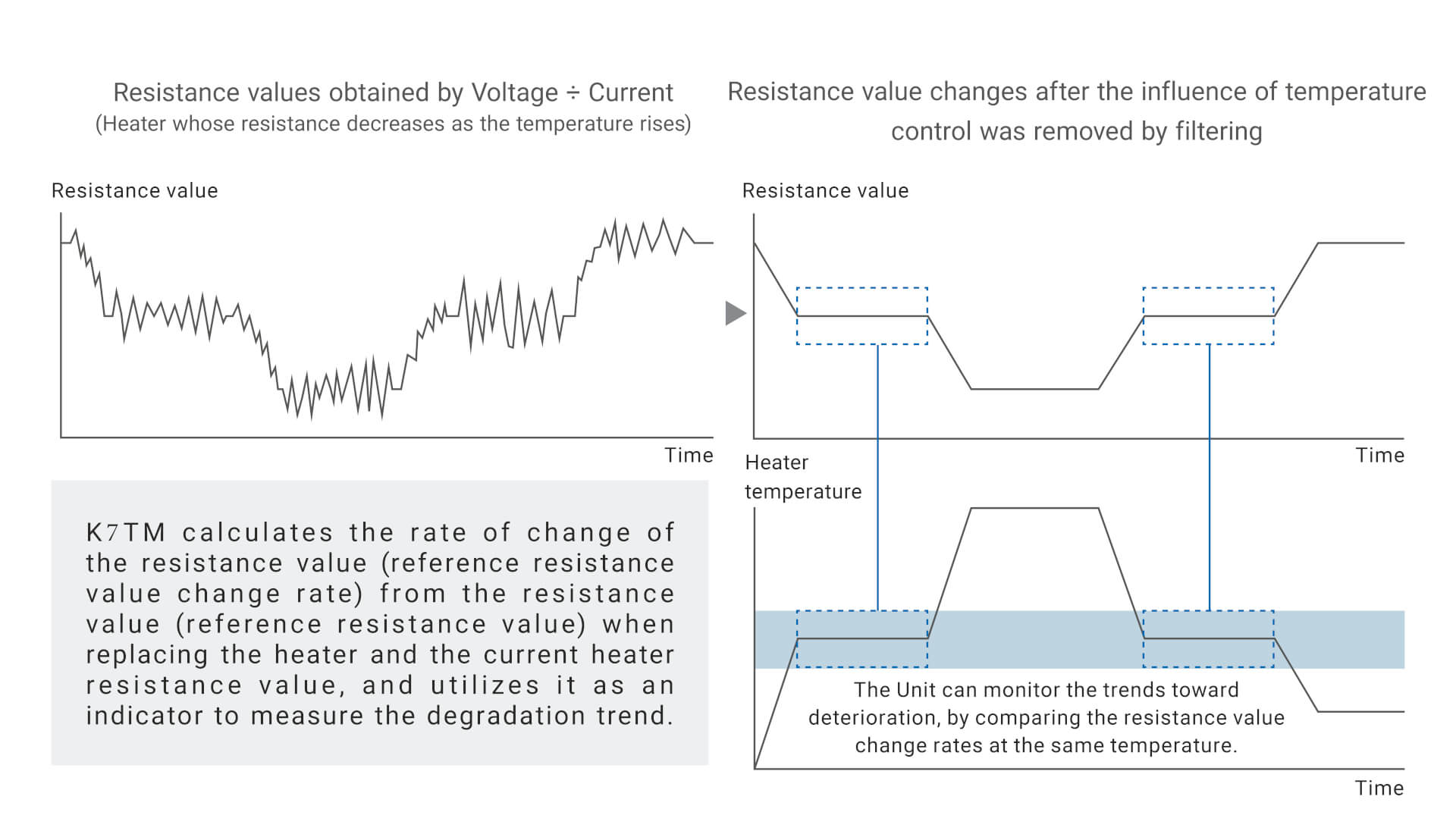

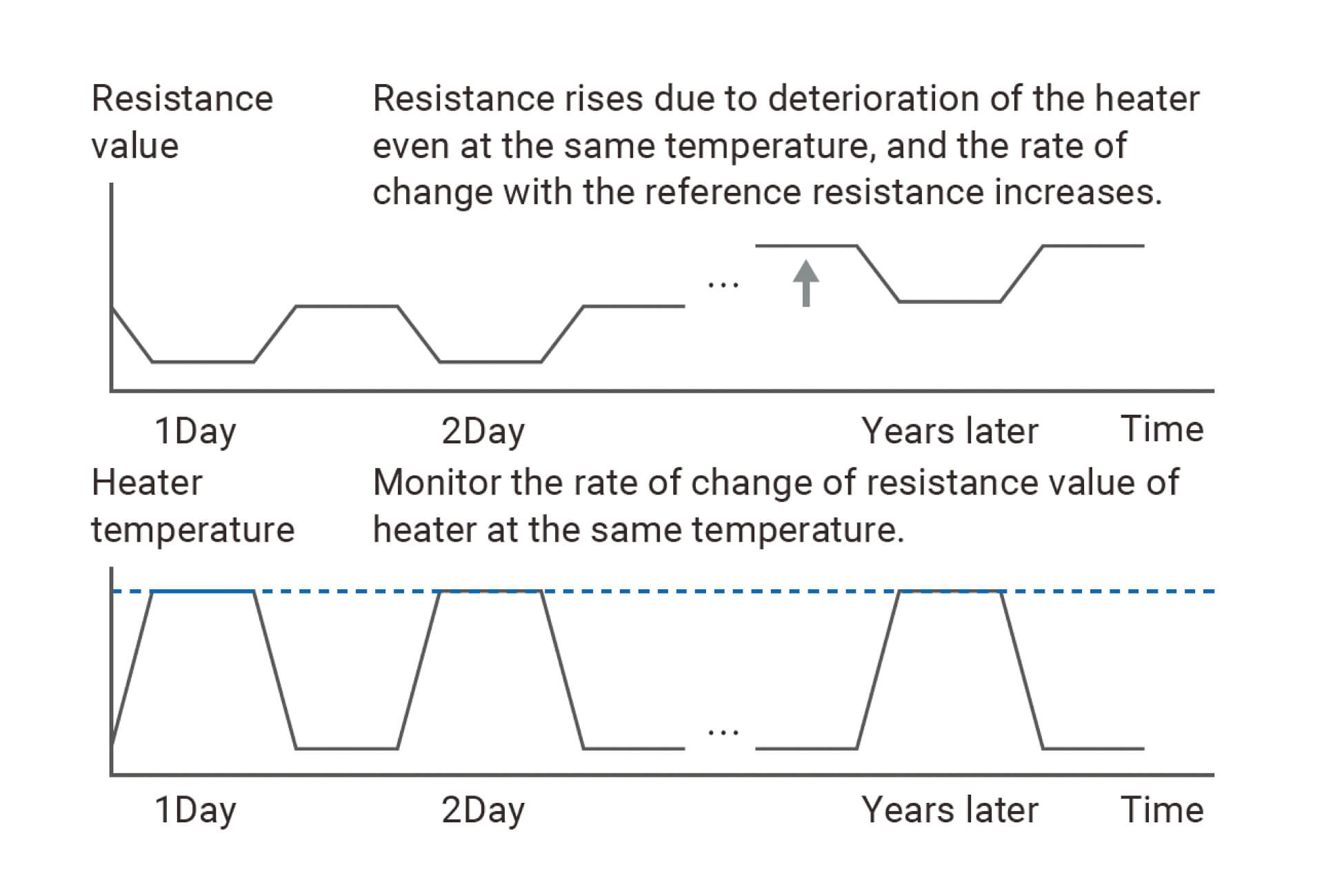

Measurement method

Heater resistance value trends

Warning and alarm display

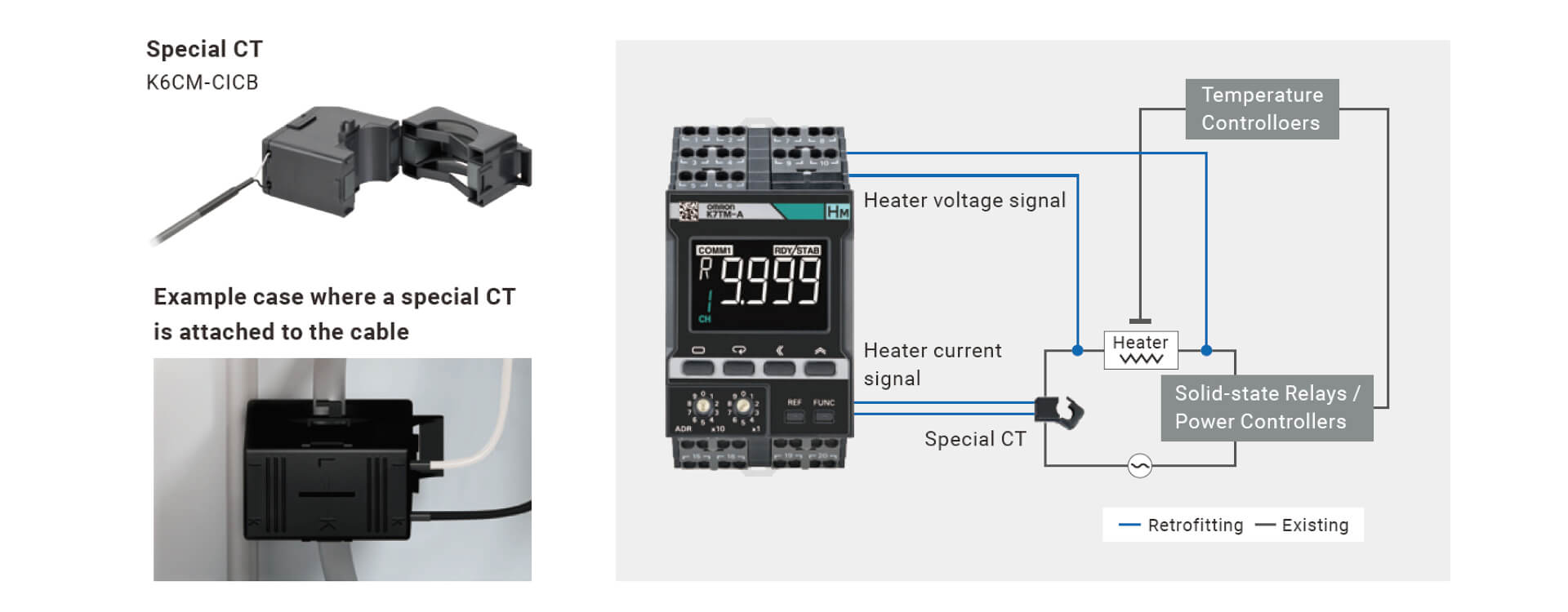

Simple retrofitting of existing devices

Acquisition of measurement data remotely via network connections

Condition monitoring devices can be configured with a single tool

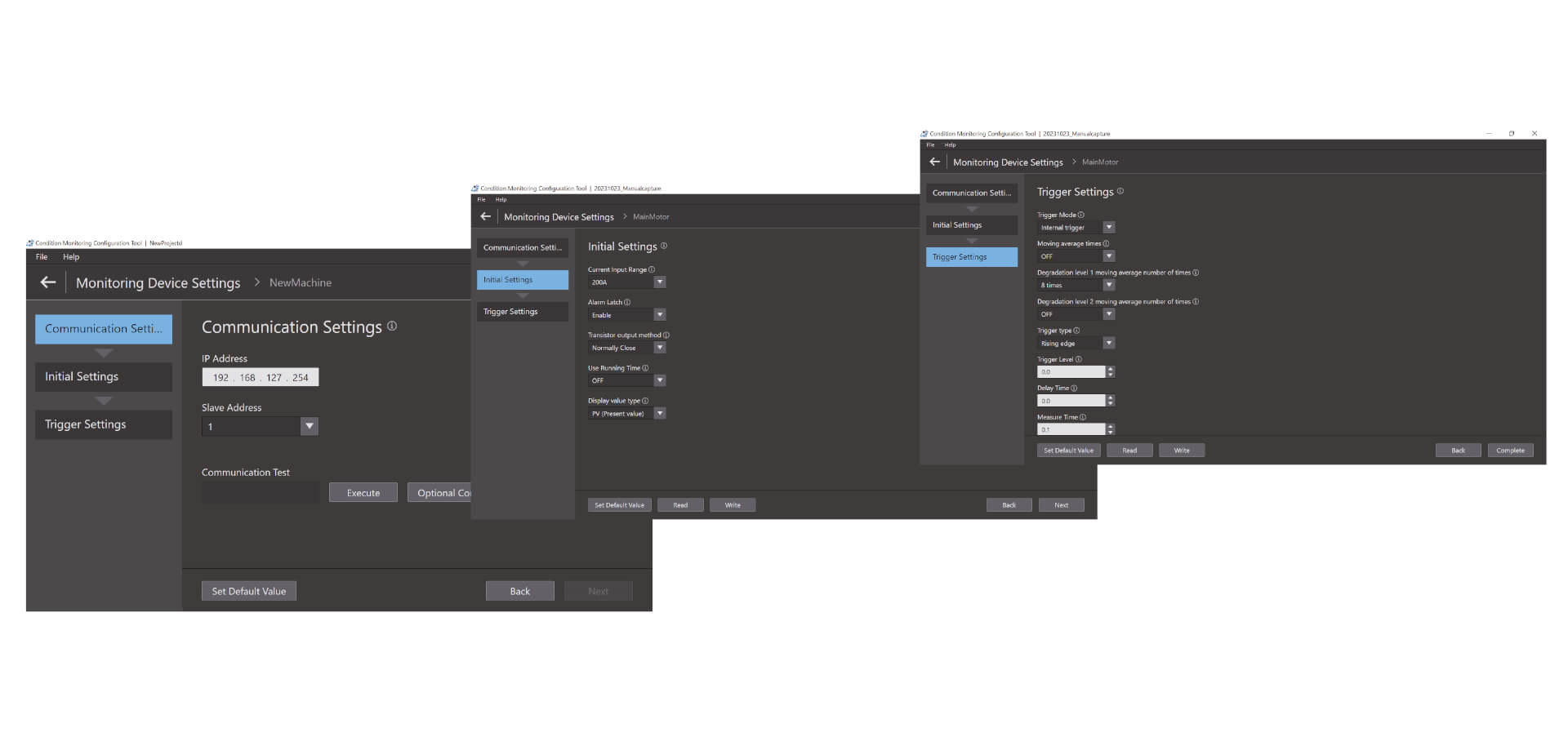

Easy three-step configuration The Condition Monitoring Configuration Tool allows for batch configuration of a wide range of condition monitoring devices, such as those for monitoring motors, temperatures, insulation, and heaters. It can be used without any special skills, reducing training effort

Easy three-step configuration

The Condition Monitoring Configuration Tool allows for batch configuration of a wide range of condition monitoring devices, such as those for monitoring motors, temperatures, insulation, and heaters. It can be used without any special skills, reducing training effort. Setup can be completed in just three steps: communications setup, initial setup, and trigger setup.*1 With its high operability, the tool boosts on-site productivity as well.