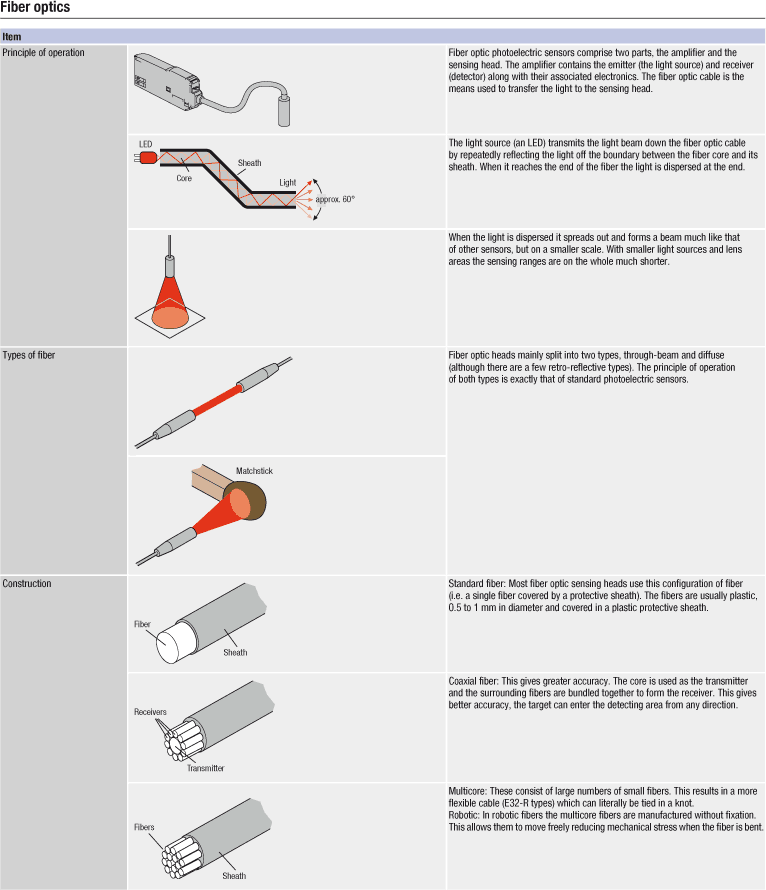

E32 speciella tillämpningar

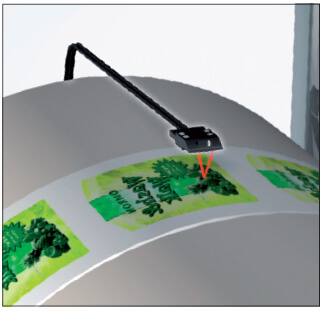

Special application fiber sensor heads

For a wide range of special applications, the task optimised fiber heads provide best fitting sensing performance and adaption to environmental requirements.

- Detection of special objects (liquids, transparent foils, etc.)

- Fiber heads ideal for colour mark detection

- Fiber heads optimised for special tasks (wafer mapping, hot reflective surface detection, etc.)

Specifications & ordering info

| Produkt | Sensing method | Shape | Size | Application | Features | Temperature range | Sensing distance | Cable length | Bending radius | Free cut | Material core | Degree of protection (IP) | Sensing surface orientation | Material sheath | Description | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

Through-beam | Square | Liquid level detection | Bend resistant | -40-70 °C | 5 m | 4 mm | Yes | Plastic | IP50 | Fluororesin | Fiber optic sensor head, liquid level detection, tube mounting 3.2; 6.4 and 9.5mm diameter, R4 bend resistant fiber, 5 m cable |

|

|||

|

|

Diffuse reflective | Threaded | M6 | Object detection | 90° cable exit, Flexible fiber, Hexagonal back, Small spot with lens | -40-70 °C | 1170 mm | 2 m | 4 mm | Yes | Plastic | IP67 | Right-angle | Polyethylene | Fiber optic sensor head, diffuse, M6 hexagonal back, right-angled head, coaxial, R4 fiber, 2 m cable |

|

|

|

Diffuse reflective | Square | Liquid level detection | -40-70 °C | 0 mm | 2 m | 4 mm | Yes | Plastic | IP67 | Side-view | Polyethylene | Fiber optic sensor head, diffuse, liquid level detection, tube mounting without diameter restrictions, R4 fiber, 2 m cable |

|

||

|

|

Diffuse reflective | Cylindrical axial | dia 6 mm | Liquid level detection | Heat-resistant | -40-200 °C | 0 mm | 4 m | 25 mm | Yes | Plastic | IP68 | Top-view | Fluororesin | Fiber optic sensor head, diffuse, cylindrical axial, diameter 6 mm, liquid level detection by contact, R25 heat resistant fiber, up to 200ºC, 4 m cable |

|

|

|

Not Applicable | Fiber on roll | dia 2.2 mm | Field assembly | -40-70 °C | 100 m | 10 mm | Yes | Plastic | Optical fiber roll, 100 m, 2.2 mm diameter, R10 fiber |

|

|||||

|

|

Not Applicable | Fiber on roll | dia 2.2 mm | Field assembly | -40-70 °C | 10 m | 10 mm | Yes | Plastic | Optical fiber roll, 10 m, 2.2 mm diameter, R10 fiber |

|

|||||

|

|

Not Applicable | Fiber on roll | dia 2.2 mm | Field assembly | Flexible fiber | -40-70 °C | 100 m | 2 mm | Yes | Plastic | Optical fiber roll, 100 m, 2.2 mm diameter, R2 flexible fiber |

|

||||

|

|

Not Applicable | Fiber on roll | dia 2.2 mm | Field assembly | Flexible fiber | -40-70 °C | 10 m | 2 mm | Yes | Plastic | Optical fiber roll, 10 m, 2.2 mm diameter, R2 flexible fiber |

|

||||

|

|

Not Applicable | Fiber on roll | dia 1 mm | Field assembly | -40-60 °C | 100 m | 15 mm | Yes | Plastic | Polyethylene | Optical fiber roll, 100 m, 1 mm diameter, R15 fiber |

|

||||

|

|

Not Applicable | Fiber on roll | dia 1 mm | Field assembly | -40-60 °C | 10 m | 15 mm | Yes | Plastic | Polyethylene | Optical fiber roll, 10 m, 1 mm diameter, R15 fiber |

|

||||

|

|

Not Applicable | Fiber on roll | dia 1 mm | Field assembly | Flexible fiber | -40-70 °C | 100 m | 1 mm | Yes | Plastic | Polyethylene | Optical fiber roll, 100 m, 1 mm diameter, R1 flexible fiber |

|

|||

|

|

Not Applicable | Fiber on roll | dia 1 mm | Field assembly | Flexible fiber | -40-70 °C | 10 m | 1 mm | Yes | Plastic | Polyethylene | Optical fiber roll, 10 m, 1 mm diameter, R1 flexible fiber |

|

|||

|

|

Not Applicable | Fiber on roll | dia 2.2 mm | Field assembly | -40-150 °C | 100 m | 20 mm | Yes | Plastic | Optical fiber roll, 100 m, 2.2 mm diameter, R20 heat resistant fiber, up to 150ºC |

|

|||||

|

|

Not Applicable | Fiber on roll | dia 2.2 mm | Field assembly | -40-150 °C | 10 m | 20 mm | Yes | Plastic | Optical fiber roll, 10 m, 2.2 mm diameter, R20 heat resistant fiber, up to 150ºC |

|

|||||

|

|

Through-beam | Cylindrical radial | dia 6 mm | Object detection | -40-70 °C | 150 mm | 2 m | 5 mm | Yes | Plastic | Side-view | Fiber optic sensor head, through-beam, cylindrical radial, diameter 6 mm, R5 fiber, 2 m cable |

|

|||

|

|

Through-beam | Square | Object detection | -40-70 °C | 10 mm | 2 m | 25 mm | Yes | Plastic | IP67 | Top-view | Polyethylene | Fiber optic sensor head, through-beam, slot type, 10 mm, R25 fiber, 2 m cable |

|

||

|

|

Through-beam | Square | Area detection | -40-70 °C | 10 mm | 2 m | 5 mm | Yes | Plastic | IP50 | Top-view | Polyethylene | Fiber optic sensor head, through-beam, 10mm slot type, 10 mm area detection, R5 fiber, 2 m cable |

|

||

|

|

Limited reflective | Square | Transparent object detection | Chemical-resistant | -10-60 °C | 20 mm | 2 m | 40 mm | Yes | Plastic | IP67 | Top-view | Fluororesin | Fiber optic sensor head, limited reflective, transparent object detection, square, top-view, R40 chemical resistant fiber, 2 m cable |

|

|

|

|

Limited reflective | Square | Liquid level detection | -40-70 °C | 2 m | 10 mm | Yes | Plastic | IP50 | Polyethylene | Fiber optic sensor head, limited reflective, liquid level detection, tube mounting 8 to 10 mm diameter, R10 fiber, 2 m cable |

|

||||

|

|

Through-beam | Cylindrical radial | dia 3.5 mm | Object detection, Wafer mapping | -40-70 °C | 4000 mm | 2 m | 10 mm | Yes | Plastic | IP50 | Side-view | PVC | Fiber optic sensor head, through-beam, cylindrical radial, diameter 3.5 mm, R10 fiber, 2 m cable |

|

Accessories

Accessories

How can we help you?

If you have a question or would like to ask for a quote, please contact us or send a request.

Kontakta mig E32 speciella tillämpningar

Tack för din förfrågan. Vi återkommer inom kort.

Vi har tekniska problem. Din formulär har inte varit framgångsrik. Vi ber om ursäkt och försök igen senare.

DownloadOffert för E32 speciella tillämpningar

Fyll i alla obligatoriska fält. Vänligen fyll i alla fält markerade med *. Dina personliga uppgifter behandlas konfidentiellt.

Tack för din offertförfrågan. Vi återkommer med önskad information inom kort.

Vi har tekniska problem. Din formulär har inte varit framgångsrik. Vi ber om ursäkt och försök igen senare.

DownloadFeatures

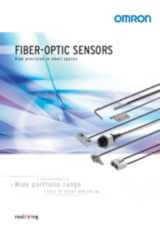

Challenging print marks

In combination with the colour/mark detection amplifier E3NX-CA, the recommended fibers for colour/mark detection allow the detection of standard and challenging marks even for complex designs or with small contrast.

Flat glass in all environments

The limited reflective fiber heads for glass detection provide a stable detection of flat glass in standard, hot or wet environment. The shapes and materials are optimized to provide the best value - performance ratio depending on the requirements.

Very small height differences

For the detection of very small height differences like labels on foils in applications where space is crucial, the small sized limited reflective sensors provide accurate detection up to 100μm resolution.

Performance comparison

Usable signal and noise

Issue 1: Increasing the difference between usable signal and noise

| The goal of any transparent sensor development is to increase the difference between usable signal and noise. |

And the operational stability of the sensor depends on how well the following factors are achieved:

|

Our solution:

At Omron we take several steps to increase the operational stability by maximising the difference between signal and noise:

- In design: circuit layouts, shielding, filtering technologies and material selection ensure a minimal background noise and highest environmental influence compensation.

- In technologies: in addition to using the retro reflective technology with standard polarisation technology, some materials e.g. PET have characteristics that additionally polarize light. This effect can be utilized further to enhance the difference between usable signal and noise.

- In production: production technologies that allow a minimal deviation from the desired target specification values ensure that the performance of a sensor evaluated at the design-in phase does not vary during mass machine production.

- In application: the selection of the fitting sensor in combination with choosing an appropriate mounting and parameter setting can further enhance the operational stability and/or detection accuracy.

Compensating for optical effects

Issue 2: Compensating for optical effects

As light travels through differing transparent materials (glass/PET) the following detection errors can occur:

- Lens-effect: transparent objects with convex shapes (e.g. shower gel bottles) can perform like a lens and allow too much light to be received by the sensor. This can result in a false reading that no object is present or it can cause a so-called double-triggering (2 signals for only one object).

- Total reflection: if the emitted light meets the surface of a transparent object at a certain angle, the light can be totally reflected instead of going through the transparent object. If the totally reflected beam hits the receiver, it can falsely result in a "no object" reading.

Our solution:

At Omron we use special coaxial optics for our higher value and application specific sensors. These special coaxial optical sensors reduce or completely eliminate the above described optical effects. Cylindrical sensors utilise the coaxial optics to prevent false signals caused by incorrect installation or turning sensors using conventional separate sender and receiver optics.

Process related requirements

Issue 3: Process related requirements

In order to select the correct transparent detection sensor taking also machine and process related issues into consideration is very important:

- Minimal space between bottles

- Conveying speed of the bottles/containers

- Object size or shape (miniature objects, flat glass, etc)

- Limited mounting space or long distances

- Hot, wet or hygienic environments

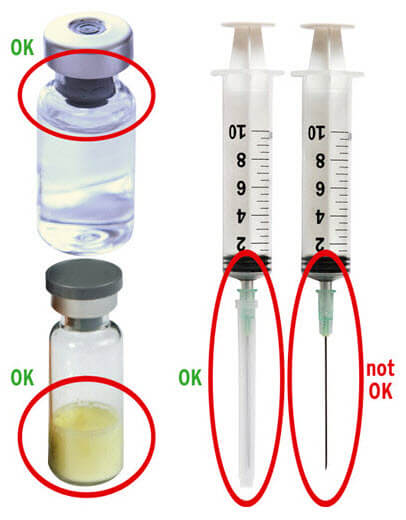

- Detection of container and content at the same time (e.g. vial and plug, vial and lyo cake, glass syringe with or without protective cover,…)

Application examples detection of 2 states with one sensor:

- State 1: Transparent container + object present e.g. plug, lyo cake or syringe cover (OK state)

- State 2: Transparent container WITHOUT object (not OK state)

Our solution:

At Omron we have a global network of application engineers. Their technical knowledge and experience will assist you and your company in making the correct product selection to fit your organisation industrial automation requirements and needs. What can we do for you?

Solution portfolio

Best choice in value for money

E3Z-B:

- For standard applications

- All transparent objects

- Excellent value for money

Best choice in reliability, flexibility, stability

E3ZM-BT:

- The "All-rounder"….stable detection of transparent objects in a wide range of applications

- All transparent objects

- Excellent chemical resistance

- The "M18 cylindrical brother" of E3ZM-BT

- Position independent detection due to co-axial optics

Best performance for dedicated applications

E3ZM-B:

- The "PET-Specialist"

- Advanced reliability due to special polarization and automatic threshold control

- Best detection performance for transparent film, flat glass in hot or wet environments or longest lifetime for frequently cleaned environments

Technical information