NX-TC/NX-HTC

Next generation of controllers

NX-TC is next generation controllers designed to achieve optimal and automatic temperature control without human intervention. NX-HTC makes one step further to prevent anomalies due to wrong machine assembly/maintenance and reduce man-hours spent to analyzing and fixing anomalies.

- Adaptive control for self-optimization of control setting due to process changes

- Specialized function for better sealing application (packaging) and for water-cooled extruders (plastic)

- Easier integration thanks to ProfiNet, Ethernet-IP and EtherCAT fieldbus support

- Monitor equipment and environmental changes, thanks to innovative temperature waveform digitalization function

How can we help you?

If you have a question or would like to ask for a quote, please contact us or send a request.

Kontakta mig NX-TC/NX-HTC

Tack för din förfrågan. Vi återkommer inom kort.

Vi har tekniska problem. Din formulär har inte varit framgångsrik. Vi ber om ursäkt och försök igen senare.

DownloadOffert för NX-TC/NX-HTC

Fyll i alla obligatoriska fält. Vänligen fyll i alla fält markerade med *. Dina personliga uppgifter behandlas konfidentiellt.

Tack för din offertförfrågan. Vi återkommer med önskad information inom kort.

Vi har tekniska problem. Din formulär har inte varit framgångsrik. Vi ber om ursäkt och försök igen senare.

DownloadFeatures

Minimize scrap by exact control of seal-jaw temperature in horizontal/vertical flow wrappers machines (NX-TC only)

-

E5_D TC: Perfect sealing temperature control for packaging machines (1)

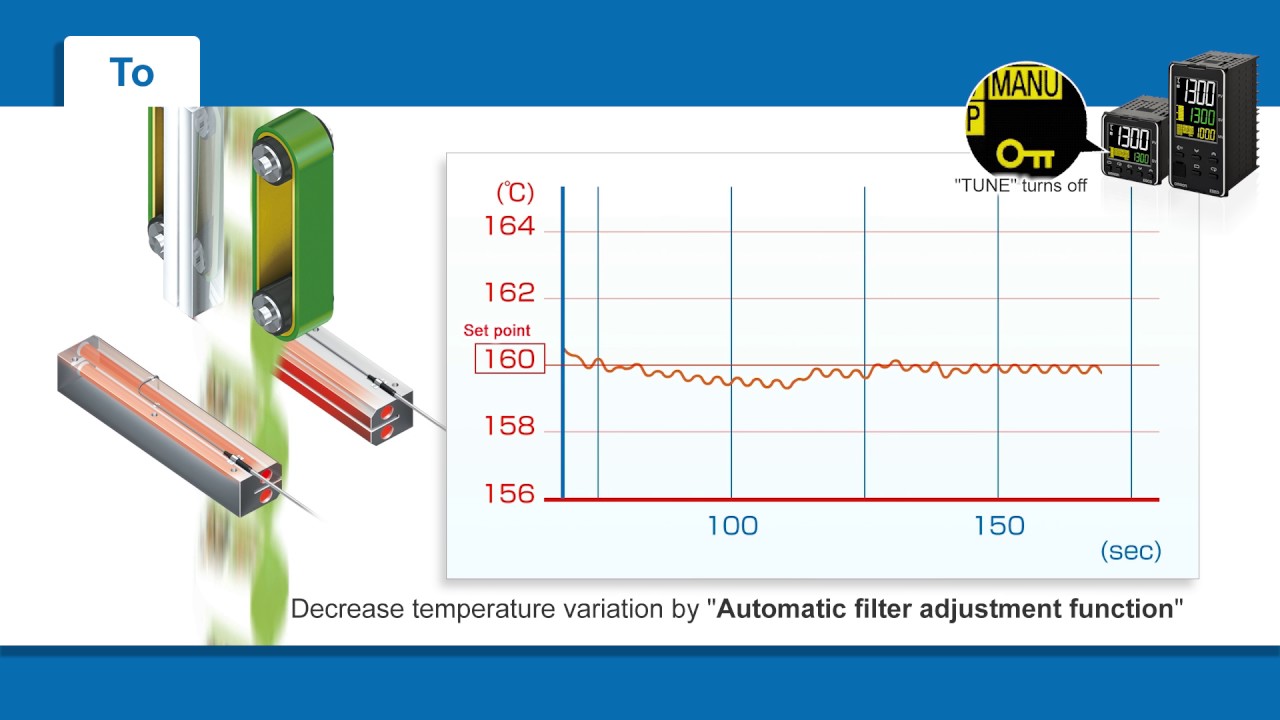

On a conventional sealing machine temperature sensors can often be located too far away from the sealing surface of the heating bar. This causes a difference between the temperature of the sealing surface and the temperature that was actually being controlled. This temperature difference and resulting sealing failures, increase as the packaging speed increases and also in correlation with thinner packaging materials or changing in ambient temperature. Thanks to the E5_D series, this issue is solved with the following approach: • bringing sensor closer to the sealing surface - thanks to special temperature sensor models for faster detection • adopting special algorithms (automatic filter adjustment function) built-in E5_D, specifically developed to suppress temperature variations. The result is a better sealing quality of the packages.

01:25

On a conventional sealing machine temperature sensors can often be located too far away from the sealing surface of the heating bar. This causes a difference between the temperature of the sealing surface and the temperature that was actually being controlled. This temperature difference and resulting sealing failures, increase as the packaging speed increases and also in correlation with thinner packaging materials or changing in ambient temperature.

Thanks to the NX-TC series, this issue is solved with the following approach:

- bringing sensor closer to the sealing surface - thanks to special temperature sensor models for faster detection

-

E5_D: Perfect sealing temperature control for packaging machines (2)

On a conventional sealing machine temperature sensors can often be located too far away from the sealing surface of the heating bar. This causes a difference between the temperature of the sealing surface and the temperature that was actually being controlled. This temperature difference and resulting sealing failures, increase as the packaging speed increases and also in correlation with thinner packaging materials or changing in ambient temperature. Thanks to the E5_D series, this issue is solved with the following approach: • bringing sensor closer to the sealing surface - thanks to special temperature sensor models for faster detection • adopting special algorithms (automatic filter adjustment function) built-in E5_D, specifically developed to suppress temperature variations. The result is a better sealing quality of the packages.

01:03

- adopting special algorithms (automatic filter adjustment function) built-in NX-TC, specifically developed to suppress temperature variations. The result is a better sealing quality of the packages.

-

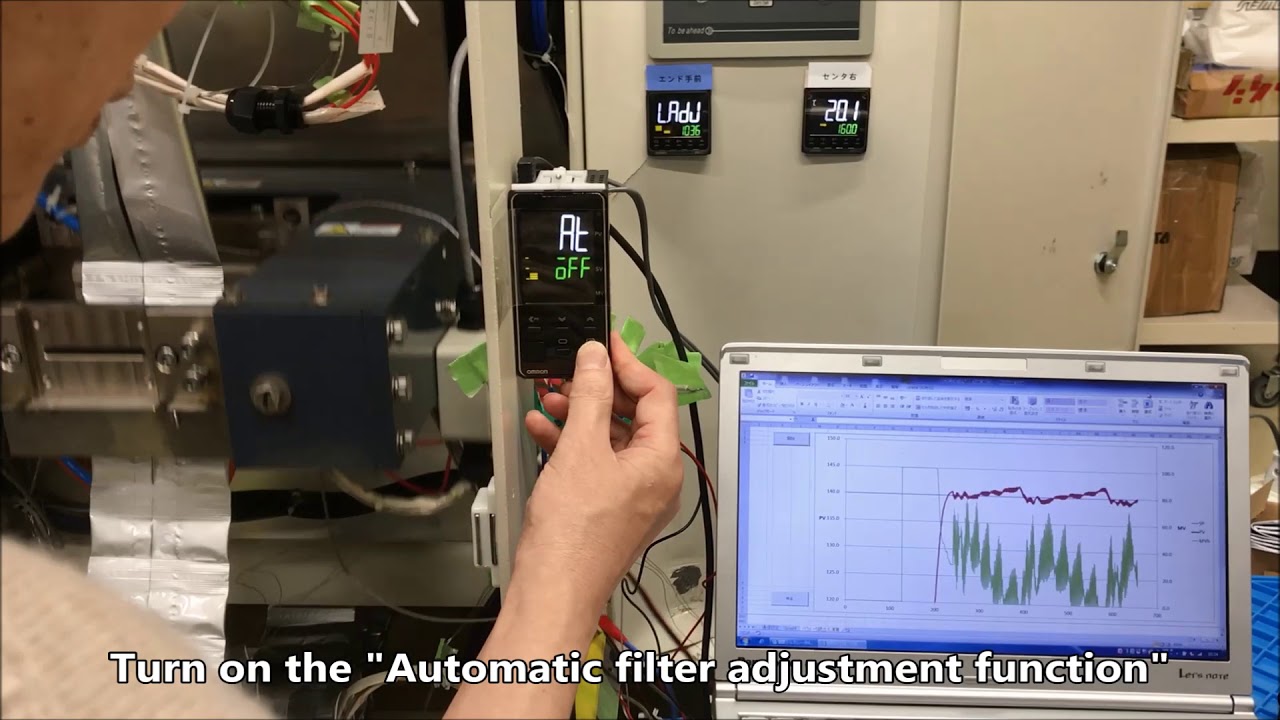

Fieldtest AI temperature controller e5-d

See the AI temperature controller in action. E5_D is the next generation controllers designed to achieve optimal and automatic temperature control without human intervention. All typical adjustments are now automated using Artificial Intelligence A.I.

01:02

See the AI temperature controller in action on the below field-test/proof movie and find out how we can control real-sealing jaw surface temperature with no impact on PID control performance.

Increase production by keeping the temperature steady - even when the packaging machine starts (NX-TC and NX-HTC)

-

OMRON NX-TC pre-boost function

Increase production by keeping the temperature steady - even when the packaging machine starts! A common challenge in horizontal/vertical flow wrapper machines. During the operation, the film absorbs heat from the seal-jaw -causing its temperature to drop at each seal. Prevent this fluctuation by synching the temperature of sealing with machine motion and activate pre-boost function with OMRON's temperature control unit NX-TC equipped with perfect sealing algorithms based on AI.

02:48

That’s a common challenge in horizontal/vertical flow wrapper machines. During the operation, the film absorbs heat from the seal-jaw -causing its temperature to drop at each seal.

Prevent this fluctuation by synching the temperature of sealing with machine motion.

Adaptive control algorithm (NX-TC only)

-

E5_D Temperature contoller: Adaptive control algorithm

With standard temperature controllers, not only do you need a long time to define initial start-up PID settings, but it is also really challenging to make the optimal adjustments without having many years of experience in this area. That’s why Omron developed the E5_D Series with “adaptive control technology”. This automatically detects changes in the process under control and adapts the PID accordingly.

01:26

With standard temperature controllers, not only do you need a long time to define initial start-up PID settings, but it is also really challenging to make the optimal adjustments without having many years of experience in this area. That’s why Omron developed the NX-TC Series with “adaptive control technology”. This automatically detects changes in the process under control and adapts the PID accordingly.

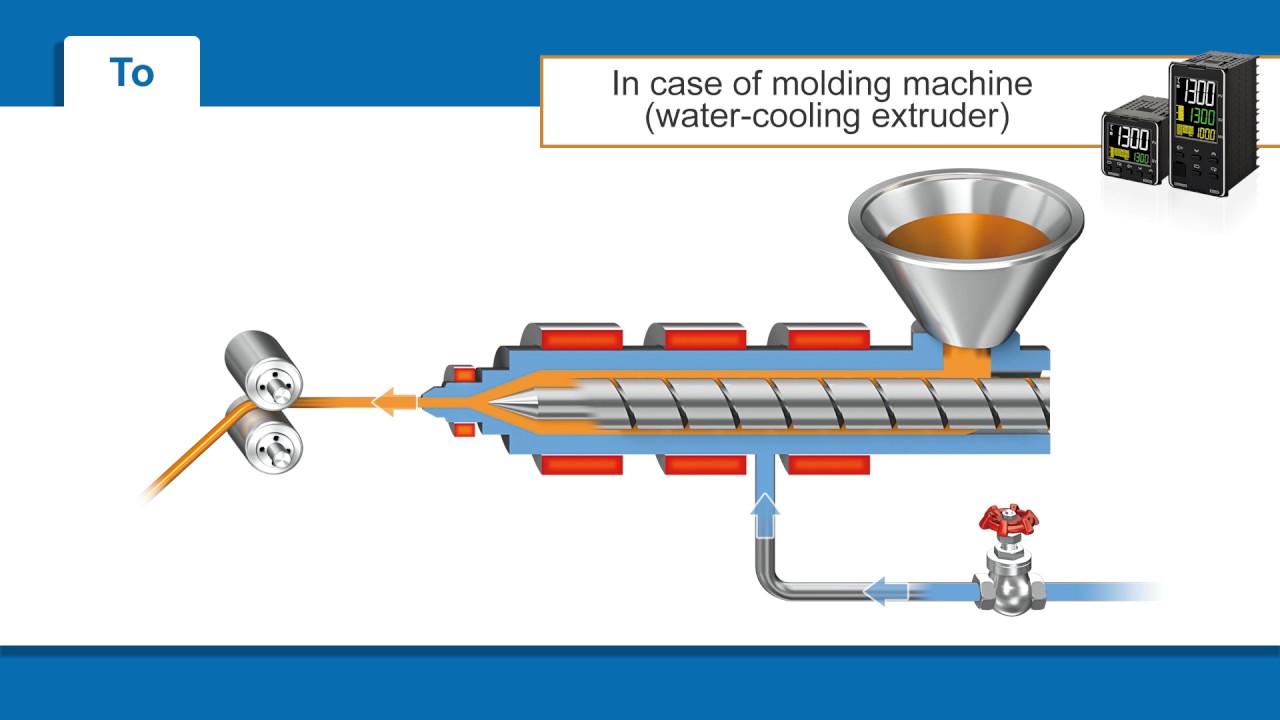

Water cooling output adjustment

-

E5_D TC: Temperature variations in molding machines minimized by a new algorithm

On a water-cooled extrusion molding machine, increased speed leads to temperature variations due to various factors such as the materials compounding and cooling water…For human operator that means repeatedly make valve adjustments to stabilize the quality. However It is really difficult to achieve high speed production while also maintaining the quality… With the E5_D, the water-cooling output adjustment function suppresses the temperature variations to a minimum and raises the production capacity with the quality maintained

01:33

On a water-cooled extrusion molding machine, increased speed leads to temperature variations due to various factors such as the materials compounding and cooling water…For human operator that means repeatedly make valve adjustments to stabilize the quality. However It is really difficult to achieve high speed production while also maintaining the quality…

With the NX-TC, the water-cooling output adjustment function suppresses the temperature variations to a minimum and raises the production capacity with the quality maintained

NX-HTC for Data-driven Maintenance decision-making

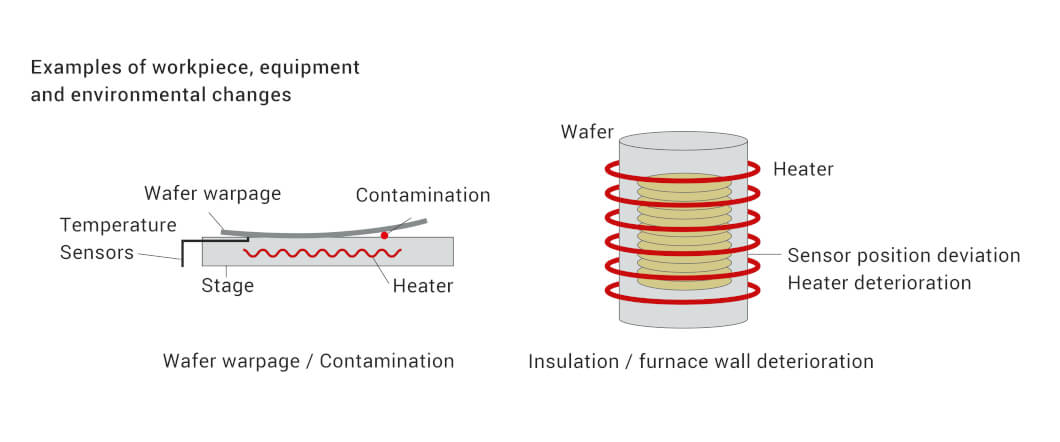

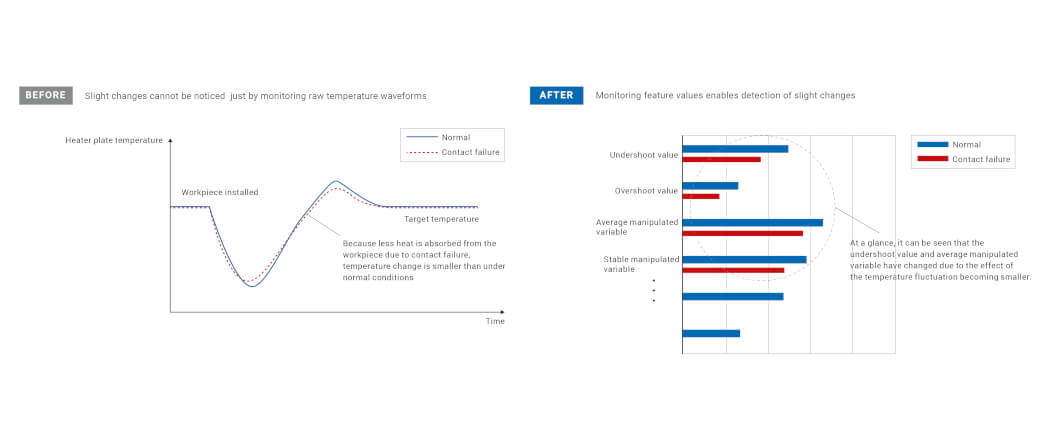

Monitor equipment and environmental changes

Providing key process information trends users can plan smarter maintenance task detecting unusual equipment conditions earlier (i.e heater degradation, wrong sensor placement, powder adhesion on sealing bar surface). NX-HTC automatically converts temperature fluctuations and manipulated variables during temperature rise into feature values.

Videos

-

NX-TC Tutorial: basic configuration and wiring check

Watch the following tutorial and learn how to set up and configure Omron’s NX-TC in Sysmac Studio and perform a wiring check.

08:32